It is ANDRITZ Feed & Biofuel that has led the innovation, and it is stimulating to work with a company that has this knowledge and experience.

Mr. Erik Gyllengahm

Site Manager, Forssjö Pellets

Since 1994, ANDRITZ Feed & Biofuel has partnered with Forssjö Pellets AB - part of the Sandåsa Timber AB group – to enable the company to produce the highest quality wood pellets for the industrial and consumer markets in a manner that is integrated into the forest and sawmill process at Forssjö Bruk outside Katrineholm city in Sweden. The company’s long-term environmental thinking, where the surplus from forest and wood industry production is used for wood pellet production, is part of its ethos to supply locally sourced, climate-neutral energy where the raw material can be traced 100% to source.

In 1994, Forssjö was looking to ensure that all of the by-product from its sawmill business could be utilised in a responsible manner, and wood pellets was the solution that was decided upon. The business of pellet production was completely new to the company at the time, so a partner was needed that could help implement a complete solution and also provide the support and experience to make sure the project was successful. ANDRITZ Feed & Biofuel was that partner.

Per Stenegard, Marknadschef / Sales Manager (Pellets) at Forssjö Pellets, still has the agenda from the first meeting he held with ANDRITZ Feed & Biofuel, which was with Lars Bloch, Plant Solution Manager, ANDRITZ Biofuel, at the end of August 1994. “It includes all of the technical details – the angle of cone and dies, speed etc. and also the original capacity that we agreed upon, which was 3 – 3.5 tph per press unit,” he said. “The first die we tried was producing 12mm pellets, and then after a few months it was 10mm pellets. Following that, over two years we progressed to 8mm pellets and ultimately were able to operate two shifts across 24 hours, with ANDRITZ Feed & Biofuel supporting us at every stage.”

Everything that was implemented at Forssjö was carried out in partnership with ANDRITZ Feed & Biofuel, and Stenegard remembers the learning curve they embarked upon together that would see the company become one of the most well-respected pellet producers in Europe. “We learned a great deal from ANDRITZ,” he continued. “When we started the factory, sawdust was sawdust. Today we have the difference between spruce and pine, different storage requirements, a wide range of different factors to consider. It was learning by doing in what has become a very big project.”

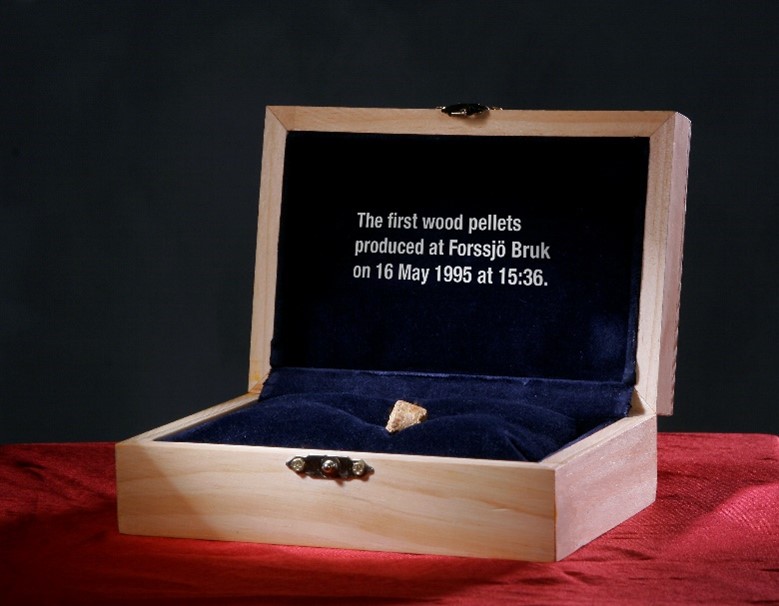

Stenegard still has evidence from the first ever production run at Forssjö Pellets (pictured), which is a box of the first wood pellets produced at the factory. They came off the line on 16 May 1995 at precisely 15.36 and were kept by him to present to the first customer of the facility on the 10th anniversary of their relationship. The factory was built with an agreement with this customer that it would be fully operational and producing product before the end of June 1995. These pellets are the evidence that this was achieved together with ANDRITZ Feed & Biofuel.

ANDRITZ Feed & Biofuel’s focus is always on continuous development and commitment to a partnership approach, which its experts to become a consultative extension of a business. It was never the case that ANDRITZ Feed & Biofuel disappeared following the initial installation of the complete plant solution for Forssjö – rather, it has remained alongside since day one to enable Forssjö to optimise its production, to identify and eliminate bottlenecks and to successfully enter new markets with a high-quality product.

Lars Bloch said: “Back in 1994 we delivered a full line of 2 x 3,5t/h capacity, consisting of two pellet presses, a hammer mill and a range of auxiliary equipment. Now, nearly three decades later we are still in partnership, helping Forssjö to increase capacity, streamline processes, and to leverage improvements and innovations that have been a part of the evolution of ANDRITZ Feed & Biofuel’s offer over the years. Our frank and honest dialogue with Per Stenegard over the years, and now also with Erik Gyllengahm, Site Manager, and his team, has been key. That trust in our ability to deliver what is best for their business has seen capacity double since 1994, through a combination of fine-tuning of processes and equipment upgrades.”

As a result of this close collaboration, Forssjö has not only grown its market share in the commercial pellet industry, but has over the years been able to enter the burgeoning consumer market. In addition, the company also identified an opportunity to supply pellets for use in the equine market – for horse’s stabling, for example. Gyllengahm said: “Our cooperation with ANDRITZ Feed & Biofuel has enabled us to expand into these markets and to deliver the quality the customers need. That trust that we have in them has allowed us to take those decisions to expand, and their equipment and technical support has made it possible.”

Mr. Erik Gyllengahm

Site Manager, Forssjö Pellets

The two pellet presses that produced the first product in 1995 were in operation for 18 and 20 years before they were replaced with newer and more efficient pellet presses. This is a testament to their durability. Upgrades and retrofits have occurred where opportunities for strategic improvements have been identified. Today, with material and energy costs rising considerably, production efficiency is paramount, and ANDRITZ Feed & Biofuel recently overhauled both pellet presses in order to enable greater capacity at lower levels of energy consumption. This greatly enhances total cost of ownership (TCO), and leaves room for further increases if required in the future.

Lars Bloch explained: “We rebuilt the pellet presses and added larger motors in order to increase capacity – which increased by 10% in the first instance. Following this, through the work of the ANDRITZ Feed & Biofuel R&D team in partnership with Forssjö, capacity further increased through the identification and implementation of process changes on the lines.”

Erik Gyllengahm added: “The changes have been incredibly successful. We optimized the speed of the die, which has really improved production, and we have been able to reduce energy consumption by some margin – by 15-20%. With ANDRITZ Feed & Biofuel we are always learning – for example, we have learned that the difference between dynamic presses and static presses is huge. It is ANDRITZ Feed & Biofuel that has led this innovation, and it is stimulating to work with a company that has this knowledge and experience. For us it has led to a production increase – which means we are going from 3.5 tons per press to more than five tons per press and still save energy.

After the upgrade of the pellet mills and the subsequent capacity increase, it was determined that further optimisation was required to overcome a production bottleneck. The original hammer mill was operating at 100% capacity, and was identified as requiring replacement to further enhance energy savings and to keep a level of capacity in reserve. Having viewed the operation from a complete solution perspective, ANDRITZ Feed & Biofuel recommended a new, larger hammer mill to enable the bottleneck to be eliminated and, as a result, product flow was returned to optimal. Today, at 70% capacity the hammer mill is able to support the production of ten tons per hour.

At 63, Per Stenegard has had a long and successful career in the industry. He concluded: “I am very fond of sayings, and one that stays with me always is that ‘to see into the future you must know your history’. Myself and the wider ANDRITZ Feed & Biofuel team have a long history together, and I am confident that as we hand over to the next generation of pellet producers, such as Erik and his team, the future will be a bright one as our partnership continues to grow stronger.”