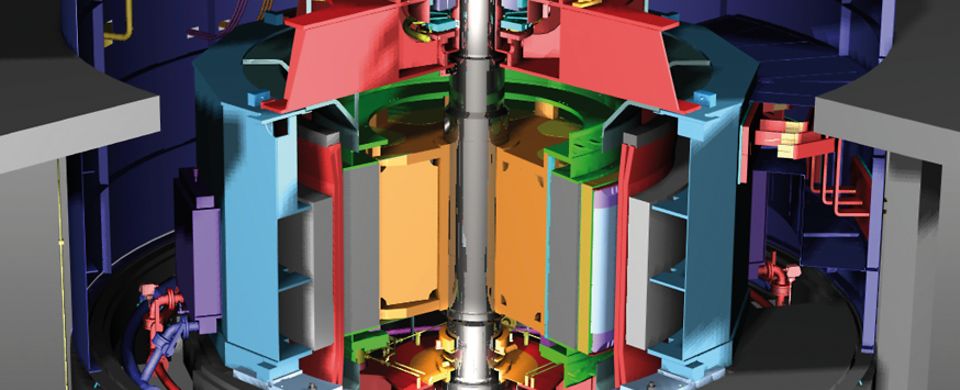

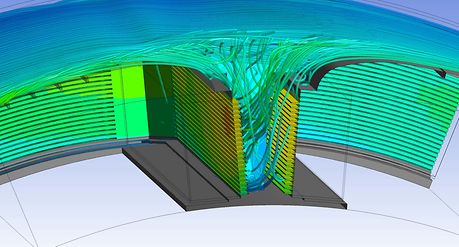

Bearing loads of up to 1000 tons require proven concepts with combined investigations of thermal, mechanical and oil flow influences using latest FSI (fluid structure interaction) methods. In our internal laboratory, such concepts can be verified on a bearing test rig facility.

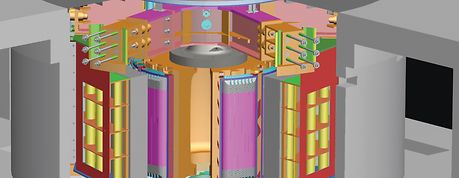

As regards mechanics, R&D concentrates on new and improved design concepts, on precise vibration and noise analysis, on highly sophisticated rotor dynamics, as well as on thermo-mechanical effects considering the huge generator dimensions and tremendous centrifugal forces. Fatigue & start-stop topics caused mainly by the additional renewables in the grids are analyzed in detail.

The actual and future market demands require highly dynamic generators for energy storage and grid stabilization. Specific concepts are hence under development such as variable speed motor generators for highly flexible pumped storage applications.

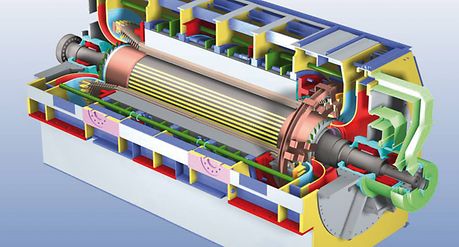

Beside generators for hydro power plants, the R&D effort for turbo generators for gas and thermal power plant applications lies on special mechanical requirements due to their high rotor speed, their rotor dynamics and cooling demands. Please also refer to the “Technical Publications”.