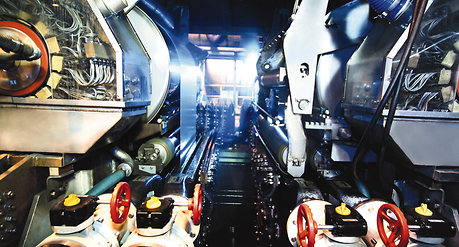

Mixed acid regeneration plants

From waste to profit

ANDRITZ Metals knows the requirements for continuous, stable, and successful operation of stainless steel pickling lines. PYROMARS is the only mixed acid regeneration system that can handle all typical waste acids from stainless steel pickling processes, and it is also easy to operate. Hence, it is second to none as the most advanced and most proven technology worldwide. ANDRITZ Metals’ newly developed ZEMAP technology transforms stainless steel mixed acid pickling into a zero-effluent process.

- PYROMARS - PYROlytical Mixed Acid Recovery System

- ZEMAP - Zero-Effluent Mixed Acid Pickling system

The advantages are numerous

| Your benefits |

No expenses for neutralization of spent pickling acid |

| No expenses for disposal of neutralization slury |

| Recovery of nitrates either as acid or reduced to nitrogen |

| Reuse of metal oxides in stainless steel melting |

| Metals recovery from waste acid up to 99% |

| Reduction of fresh acid demand to 20-25% |

| Return on investment approx. 2-3 years |