Who benefits from Metris OPP?

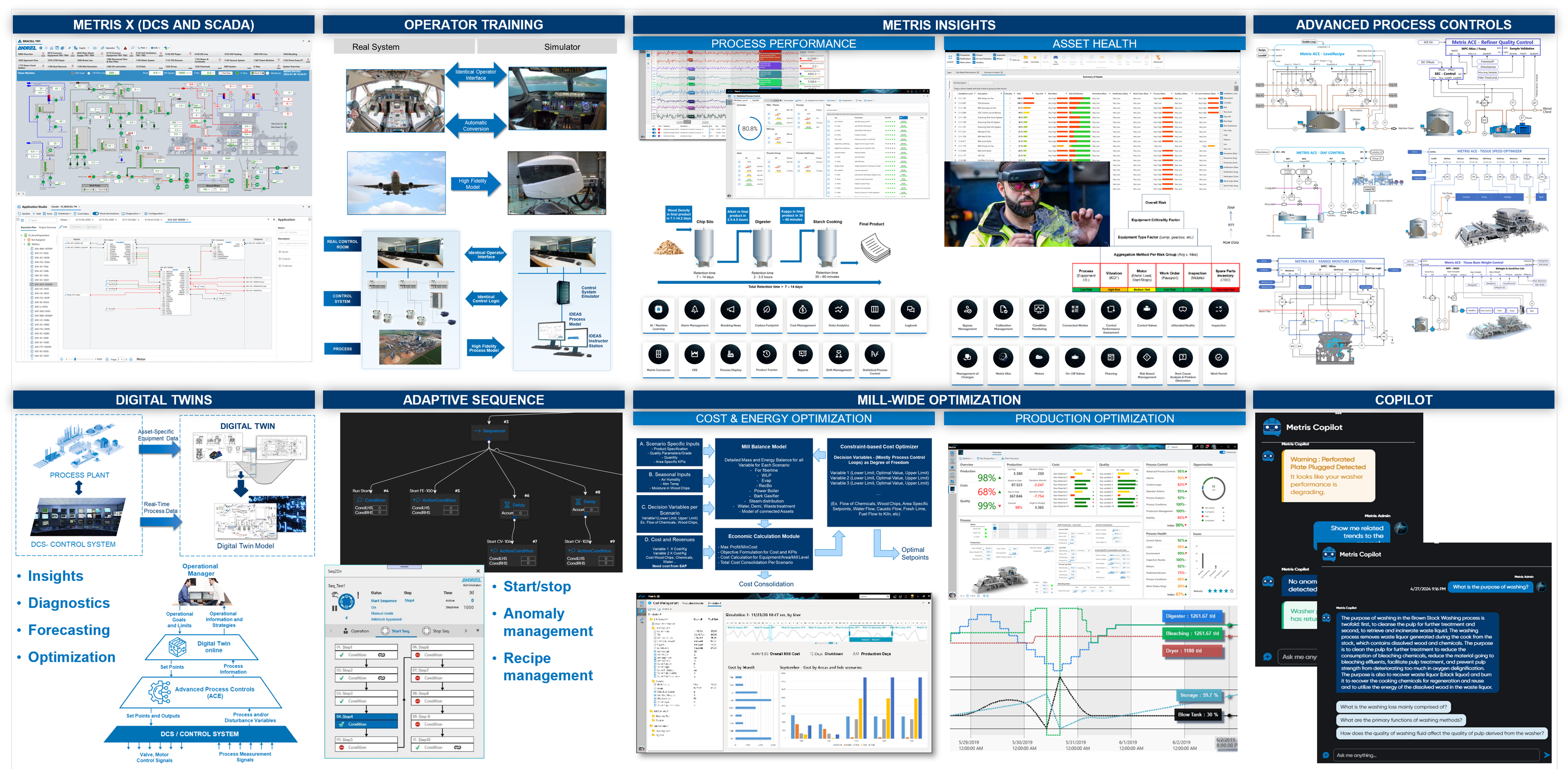

Managers can access real-time dashboards for KPIs, balanced scorecards, and project management features.

Engineers benefit from advanced analytics such as data mining, statistics, and power spectral density to enhance efficiency. The alarm system alerts operators to urgent process deviations, while the Data Historian collects and visualizes big data for quick insights.

Operators and supervisors use tools like the Logbook to improve daily operations, solve recurring issues, and train staff. Smart controls support start-up sequences, diagnostics, root cause analysis, adaptive set-points, predictive controls, and neural networks.

Field operators and technicians gain from Augmented Reality support, real-time diagnostics, and remote assistance, enabling timely improvements.