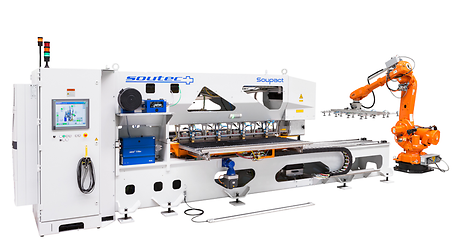

SOUPACT Compact Laser Welding System

Designed for manual operation, but upgradeable to semi- or fully automated version, with possibility to integrate add-on process module(s) such as dimpling station, turning-over device, laser marker, etc.

The SOUPACT system is the right solution for small investment with reduced outputs.

SOUPACT Compact Laser Welding System for Linear Seams

SOUPACT system is integrated with ANDRITZ Soutec’s over 30 years expertise and various patented/unique technologies.

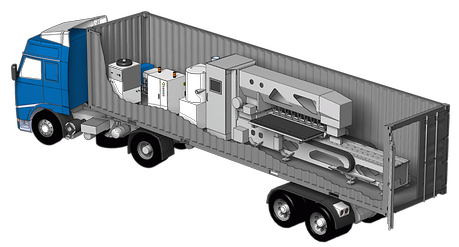

The entire machine can be packed in a 40’ container for shipping. Thus, the shipping cost is reduced significantly.

In addition, the SOUPACT system can be dismantled easily and brought to another location in a 40’ container. It is the ideal machine for back-up and production flexibility.

The continuous measurement seam tracking and quality control system guarantees a stable welding process, meeting the highest quality requirements. Gaps of ≤0.3 mm between the sheet metal are closed with SOUFIL filler wire system. With the aid of our continuous gap closing and vision system, we are able to regulate the wire speed to ensure that sufficient material is always present in the melting pool.

Clamping system in the SOUPACT

Benefits at a glance

- Globally unique edge tracking and quality control system

- SOUFIL adaptive wire feeding for perfect welding under difficult edge conditions

- Short change-over times

- Expandable by modules up to the overall concept as a fully automatic welding machine

- User-friendly control with fault visualization and remote maintenance for all modules

- Designed for solid-state laser with high efficiency at lowest operating costs

Simple packaging in standard 40’ containers, and therefore fast commissioning at production site

Technical data

| Parameter | Value |

| Max. seam length | 2,500 mm |

| Min. blank length | 100 mm |

| Max. blank width thin parts | 1,700 mm |

| Max. blank width thick parts | 700 mm (with the option of being enlarged) |

| Min. blank width | 100 mm |

| Sheet metal thickness | 0.65 - 3.0 mm (optional up to 5.0 mm) |

| Max. parts per cycle | 1 standard (2-4 optional) |

| Max. seams per cycle | 1 standard (2-4 optional) |

| Laser source | fiber laser, disk laser, or diode laser |