Flexible machine concepts for the lamination of nonwovens

Depending on the end-use, ANDRITZ offers two different state-of-the-art lamination technologies: thermal and ultrasonic bonding

Lamination combines at least two different materials in order to achieve a new composite. Due to the wide range of raw materials used (nonwovens, foils, reinforcement webs, paper, etc.), a state-of-the-art laminating device and a raw material handling system are critical to success. ANDRITZ Küsters neXcal calenders enable a manufacturer to ensure the highest production flexibility and end product quality.

Lamination process

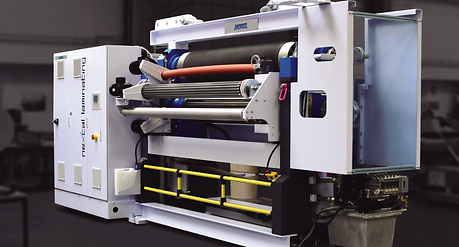

neXcal laminating

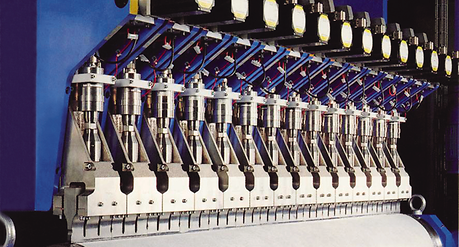

neXcal ultrasonic

Thermo-laminating calender

In the thermo-laminating process, a minimum of two layers are bonded together between two rolls by pressure and temperature. Using deflection-controlled Hot S-Roll technology and operator-friendly recipe control, the calender delivers the best reproducibility at all times.

A typical application is the production of roofing materials.

Ultrasonic calender

Bonding and laminating with ultrasonic vibrations is a thermo-mechanical process. The energy to produce the laminating effect is transmitted to the fabric via high-frequency vibration. Heat is generated in the gap between the weld-horn and the roll surface at the engraving point due to the friction of the fibers against each other. The fibers melt and are welded together precisely at the engraving point. There is no further heat impact on the surrounding material, making it possible to laminate thermo-plastic materials with different softening and melting points.

Typical applications are the production of filtration materials, such as vacuum cleaner bags, automotive filters, and similar products.