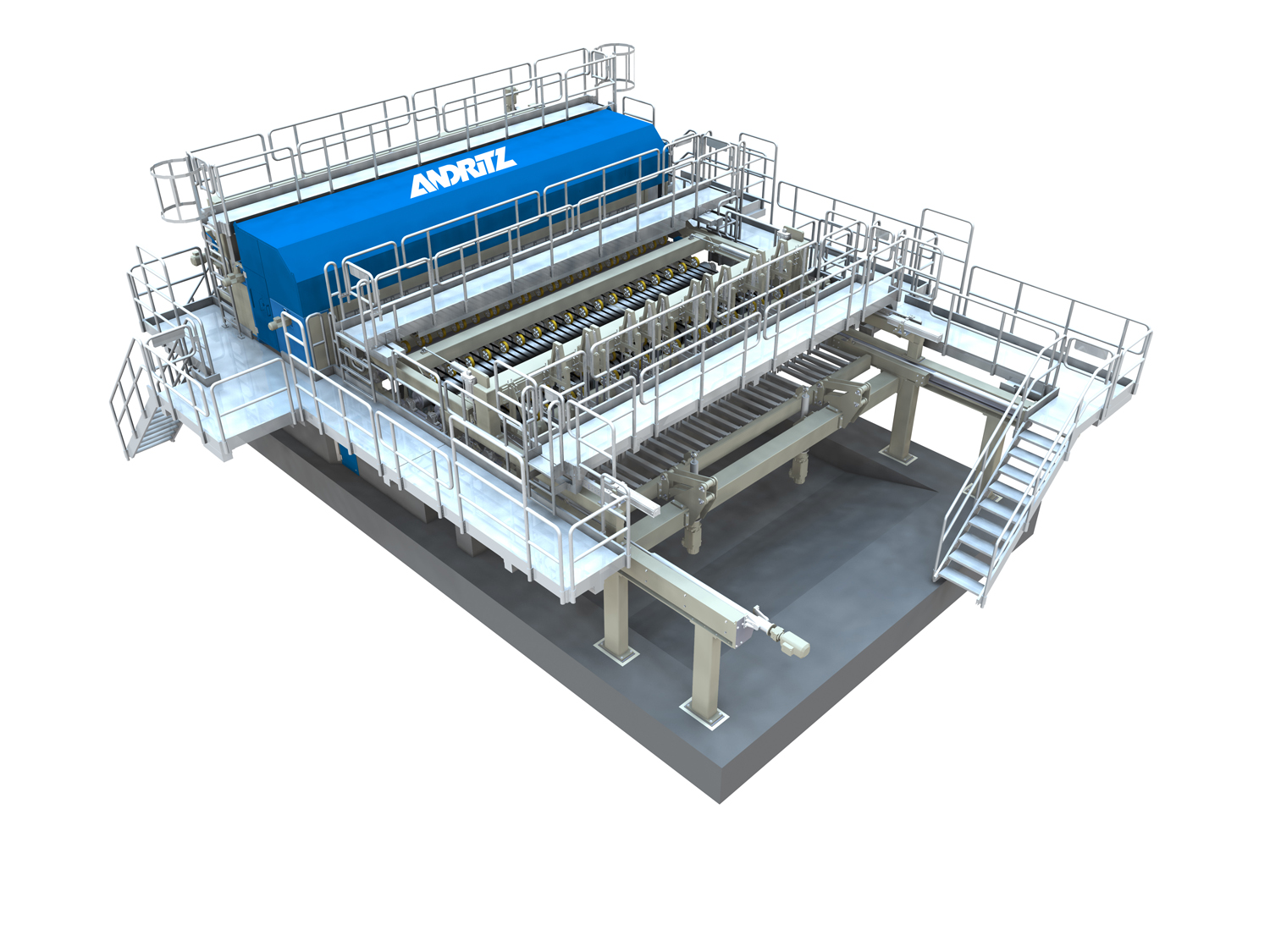

ANDRITZ high-speed cutter-layboy for market pulp

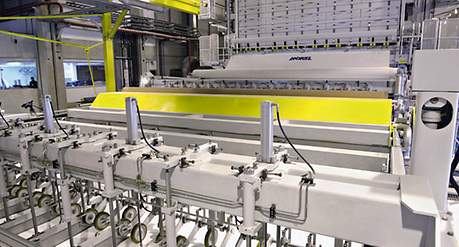

The ANDRITZ cutter-layboy operates fully automatically

ANDRITZ cutter-layboy technology ensures high performance and safe operation of market pulp sheet drying plants.

Cutter layboy

The system can be operated in fully automatic mode controlled by the ANDRITZ BaleMatic pulp finishing control system. The ANDRITZ cutter-layboy is engineered for reliable operation even at highest speed with minimal maintenance requirements.

The ANDRITZ cutter-layboy is a fully automatic system for

- Receiving the pulp web from the air dryer

- Slitting the market pulp sheet in longitudinal direction

- Cutting the market pulp sheet in cross direction

- Stacking the sheets and wrappers on the main table of the layboy

- Weighing and/or counting the sheets during stacking

- Discharging the stacked sheets as bales to the baling line(s)

Cutter-layboy and sheet dryer

ANDRITZ cutter-layboy – main features

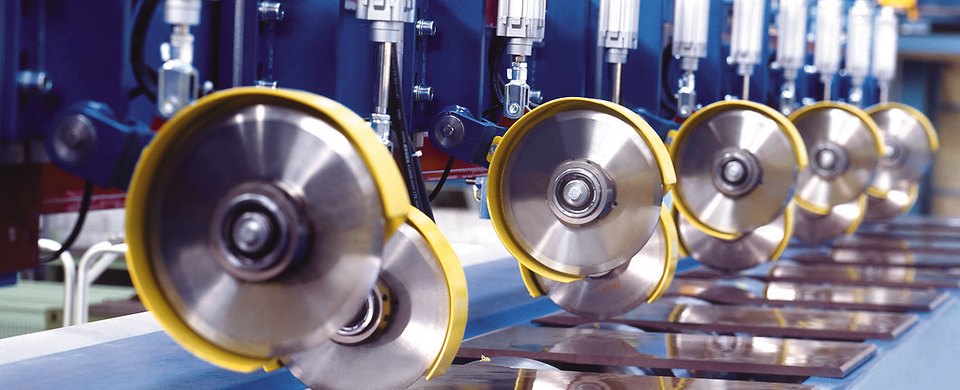

- Automatic tail threading

- Easy maintenance and short knife changing times

- Simple and reliable design

- Precise sheet cross-cuts due to the helical design of the fly knife (scissors cut)

- Fly knife equipped with two knives

- Accurate knife clearance micro adjustment with high-precision spindles

- No temperature deflection at the cross-cutter due to anvil heating and fly knife heating system

- Automatic plug-removal for low down-time

- Low bale weight variations due to automatic discharge system controlled by weighing system or sheet counting

- Short changing time between producing sheets to producing wrappers

- Noise protection hood

- Dust removal system

With a speed of up to 300 m/min and a maximum width of more than 9.4 m, the ANDRITZ cutter-layboy meets the requirements of any state-of-the-art market pulp drying and pulp baling line.

ANDRITZ BaleMatic pulp finishing control system

The ANDRITZ BaleMatic has been developed specifically for pulp finishing systems. A fully automatic PLC (Programmable Logic Controller) system for high reliability controls the BaleMatic. Sophisticated programming ensures optimum results for time-critical machine functions, as well as safe and comfortable operation of the equipment. Production and system data are transmitted to a DCS or mill-wide information system via an interface. BaleMatic uses standard field bus technology.