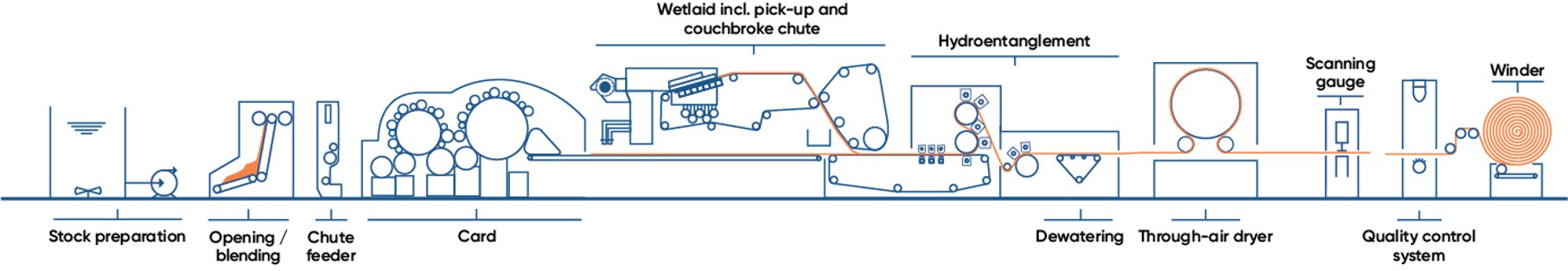

Maximize your productivity with neXline wetlace™ hybrid

Invest in the state of the art wetlaid hybrid line, to get an alrounder for the growing wipes market.

In the wetlaid hybrid line, ANDRITZ combined the know how of years of success in wetlace and spunlace, to create a technology, that is the perfect all-round solution for wipe production.

Through an investment in this state of the art technology, you will not only get the equipment for classical wetlace and nonwoven processes, you will also be able to combine e.g. pulp-layer with other nonwoven types, short fiber with long fiber layers and different types of nonwovens.

2D-configuration of ANDRITZ neXline wetlace™ hybrid

© ANDRITZFlexibility of wetlace hybrid

neXline wetlace hybrid gives the highest degree of flexibility. The line can be used as a spunlace line for conventional wipes or those made of natural fibers, as a wetlace process for flushable wipes or in combinations of nonwoven materials. This means you are ideally equipped to meet the demands of the market now and in the future.

PROCESS | DESCRIPTION | PRODUCTS/OPTIONS |

Wetlace™ | Wetlaid plus hydroentanglement | Classical WetlaceTM process |

Composite | Unwinder plus wetlaid plus hydroentanglement (Wetlace + unwinder for additional layer) | Combines e.g. pulp-layer with other nonwoven types |

Composite | Unwinder plus drylaid plus hydro-entanglement (Spunlace + unwinder for additional layer) | Combines different nonwoven types |

Composite | Wetlaid plus drylaid plus hydro-entanglement (Spunlace + Wetlace) | Combines short fiber with long fiber layers |

Spunlace | Drylaid plus hydroentanglement | Classical nonwoven process |