MCT - Modular cooling technology for submersible motors

Efficient and cost-effective cooling of submersible motors is a constant source of discussion by well and mine operators. Derating is a less-than-ideal solution. In addition to high capital and energy costs, the overlarge, downgraded motors usually require a larger well diameter. Oil cooling needs careful consideration as well – any failure can cause ecological damage.

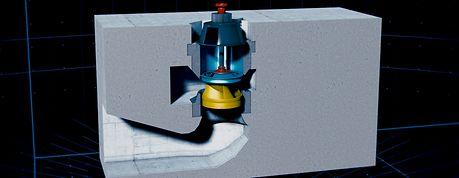

ANDRITZ motors are equipped with the innovative modular cooling technology (MCT ), enhancing durability and also being the most efficient possible means of cooling submersible motors. The absolutely maintenance-free motors use potable water as cooling fluid and can be installed in media up to 75° C. A pump impeller brings movement into the cooling circuit and thus provides flow in the right direction. Our own development cooling channels ensure heat absorption at all thermal sources and heat evacuation, as well as providing optimal heat conduction through the outside of the motor to the flow medium. The additional use of heat exchanger modules allows precise dimensioning of the cooling capacity. For more information on our modular cooling technology please have a look at our brochures in the sidebar or contact us directly.