Micro fluid system (MFS)

ANDRITZ offers the Micro Fluid System (MFS) for adding enzymes, vitamins, fats, and oils to the feed pellets after the drying/cooling process. The system ensures precise and accurate fluid distribution.

The micro fluid system is a post pellet liquid application and is designed for continuous spraying of micro - and macro fluids, such as enzymes, amino acids, vitamins, aromatics, fats, and oil onto animal feed pellets or granulates after the drying/cooling process

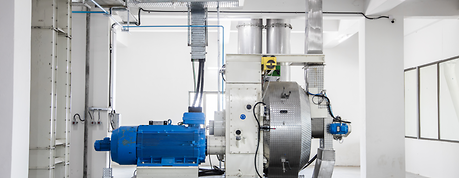

ANDRITZ micro fluid system

Benefits of adding micro ingredients after pelleting:

- More flexibility in the feed pelleting line

- Increased capacity as multiple feed variants can be produced without restarting the process

- Post-pellet application of heat-sensitive micro-ingredients is more cost-saving compared to liquid application before pelleting (pre-heat treatment)

Advantages of the ANDRITZ micro fluid system

- High fluid dosing accuracy even at low flow rates

- Precise fluid distribution

- Operation flexibility

- Compact design making it easy to install in all facilities

- Hygienic design and easy access for cleaning

- Computerized control system providing documentation and diagnostics