Get into care business with air-through-bonding

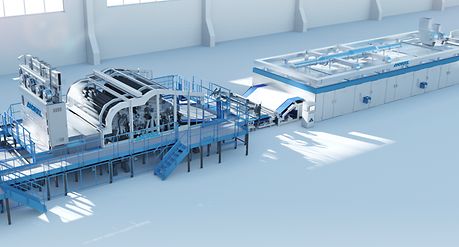

Innovative solutions for various products of the growing hygiene market - with ANDRITZ neXline air-through bonding eXcelle and neXline air-through bonding aXcess

In daily life, we find products using air-through bonding technology everywhere we look. The hygiene market requires products with a high level of uniformity, softness, bulkiness, and tensile strength. Due to population growth and aging as well as the rise in the standard of living, these products respond perfectly to the quality level requested for baby diapers, feminine hygiene or adult incontinence.

ANDRITZ offers tailored made air-through bonding with eXcelle lines for high capacities and aXcess lines for small and medium capacities.

ANDRITZ offers you customized solutions: For the production of hygiene products, we can deliver a tailor-made, Air-Through-Bonding (ATB) process. It makes use of the vast expertise that ANDRITZ has to offer in a wide range of hygiene nonwovens technologies, such as web forming and finishing (spunlace, spunlaid, spunjet, wetlace), and converting (baby diapers, feminine hygiene, adult incontinence).

YOUR BENEFITS

• Customized to meet your requirements for fiber range, throughput, web

qualities, and so on

• Consistent web qualities

• Air management system

• Enhanced visibility

• Easy accessibility for maintenance

• Highest uniformity of temperature and air-flow

• Superior softness with SoftJet technology

• Easy access to main machinery components

• Modular system

• Flexible due to the different heating systems

ANDRITZ Air-through-bonding-line eXcelle

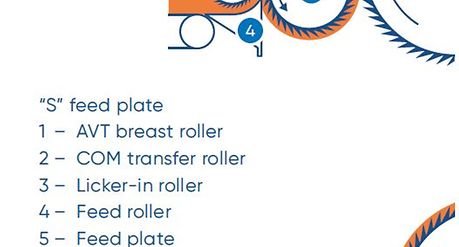

Opening & Blending for Air-through-bonding

It all starts with fibers: To spread them evenly on the way to the web former, you need a carefully designed process. With opening, blending (APC), feeding and carding technology from ANDRITZ, your nonwovens benefit in every step.

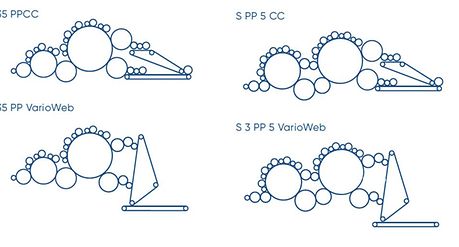

Complete range of cards for Air-through-bonding

ANDRITZ has the matching card for you: With carding power

alternatives (single or double card set-up), different web structure

solutions, and different number of doffers, we always find the

matching solution.

Alternatives for carding power

Alternatives for card feeding sections

State-of-the-art in bonding for Air-through-bonding

The oven is a very important machine in the ATB process: It must bind the still fragile and sensitive carded web smoothly into a stable nonwoven product – without reducing its high-lofted character and superior softness.

Go to ANDRITZ drying technology

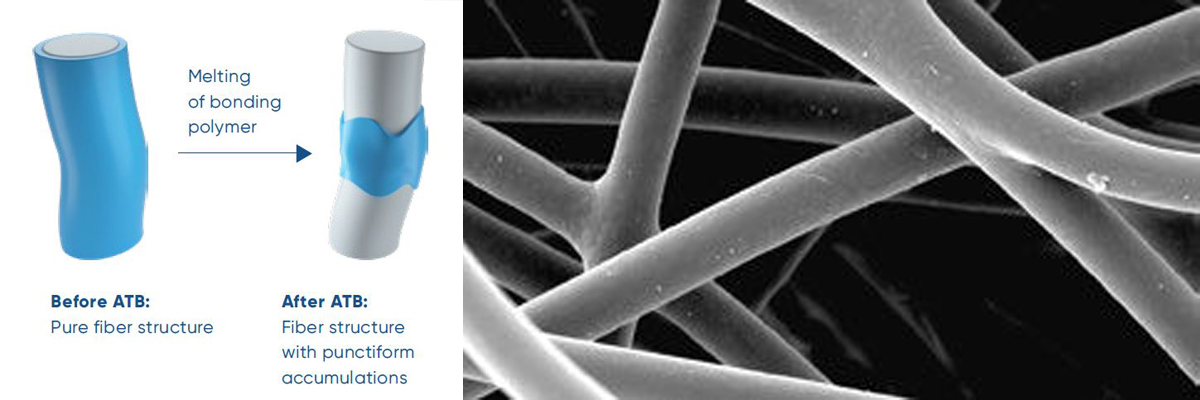

Bonding Process

Once in the oven, the hot air

activates the low-melt polymer

inside the fiber matrix. It flows

towards and gathers at the point of fiber contacts, where these accumulations then form the bonds between the individual fibers.

If you would like to learn more about ANDRITZ air through bonding, please have a look at our brochure. The most important machine elements for air-through bonding can also be found under ANDRITZ cards and ANDRITZ dryer.

Bonded fiber after Air-through-bonding

Two highly sophisticated oven systems

The fragile structure of the unbonded nonwoven web calls for a suitable transport medium: this can be either a flat oven system using an air-permeable conveyor belt or an Omega oven system with a perforated and / or sievefabric covered drum surface. ANDRITZ’s portfolio can offer you the flat as well as the Omega design, both as best suitable for covering all your requirements as a hygiene nonwoven producer. Depending on your demand, the ovens can be equipped with either indirect heating (electrical power, thermal oil) or direct heating (natural or liquid gas). A common feature of the flat and Omega designs is the one-sided, airthrough ventilation, which is typical of air-through bonding processes in the hygiene market.

The new ANDRITZ SoftJet air guidance offers you an additional advantage in flat oven systems. Even the most sensitive fiber blends and matrix structures retain their high-lofted character and superior softness after the air-through bonding process.