Virtual Tour Technical Center

Make your own walkthrough & discover our Technical Center virtually

Make your own walkthrough & discover our Technical Center virtually

The neXline needlepunch pilot line includes a high-performance eXcelle double card designed to run short and long staple fibers with a very uniform web aspect despite throughput capabilities in excess of 500 kg/h/m. It can be set to provide highly uniform webs with MD/CD ratios of less than 3:1. The line is capable of producing needled felts with low to high elongation percentages, with high tensile strength values. Final MD/CD tensile strength ratios of 1:1 will be possible once the felt reaches the winder.

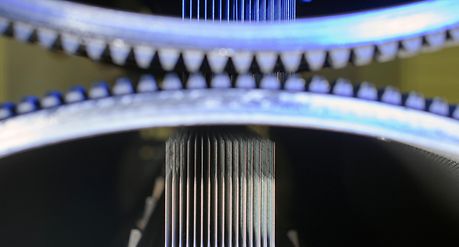

With the upgrade and re-design of the technical center, among others, also the brand new ANDRITZ PA.3000 cylindric pre-needleloom and the web optimization system ProWin.

Upgraded Technical Center for Needlepunch at Albeuf/France for a many kind of trials for various industries

The crosslapper allows high production speed, even with condensed or randomized carded webs.

The ProWin™ automatic web weight correction system is now available in the pilot line. ProWin™ works with a closed loop control system, coupled with the new ANDRITZ gauge, which handles machine-direction and cross-direction control. The pilot line also includes state-of-the-art opening and blending equipment as well as an automatic accumulator, slitter, and winder.

In addition, ANDRITZ also provides in its Technical Center the SDV-2+2 double-velour needleloom with fast offline or inline production (with great versatility), as well as improved loop quality and regularity, meeting the most demanding requirements of the automotive industry.

The Zeta drafter is designed for speeds of over 40 m/min and also has a very strong drafting capability, thus minimizing aspect distortion during fabric elongation. Furthermore, the A.50-R and A.50-RS needlelooms provide capabilities to needle from one side only or from both sides.

The pilot line also includes state-of-the-art opening and blending equipment as well as an automatic accumulator, slitter, and winder.

Close up: ANDRITZ PA.3000 cylindric pre-needler

The unique ANDRITZ ProWin™ for web optimization

ANDRITZ SDV 2+2 double velour needleloom

ANDRITZ Zeta Drafter