Be innovative with chemical recycling

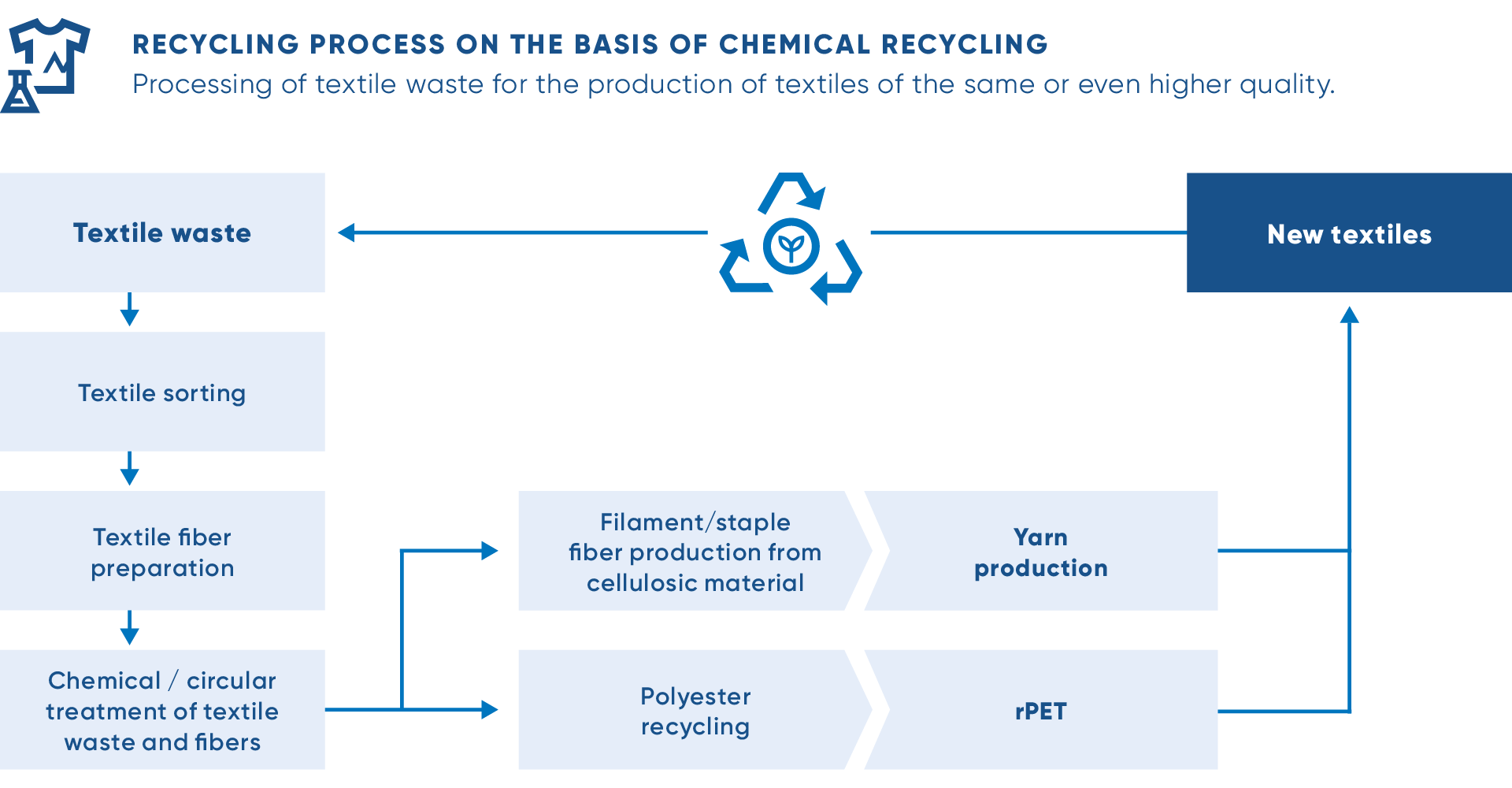

Chemical recycling of textile waste is a vital, emerging business area. It is the piece of the puzzle that completes the picture of textile-to-textile circularity. This is why it is also called circular recycling: the recycled waste completes a full circle from raw materials to textile, to textile waste, and back into raw materials.

CHEMICAL/CIRCULAR RECYCLING PROCESS

Recycling Process

Chemical and mechanical processes are fully complementary in the drive to achieve the desired results, but the addition of chemical treatment is certainly a game changer for textile-to-textile recycling.

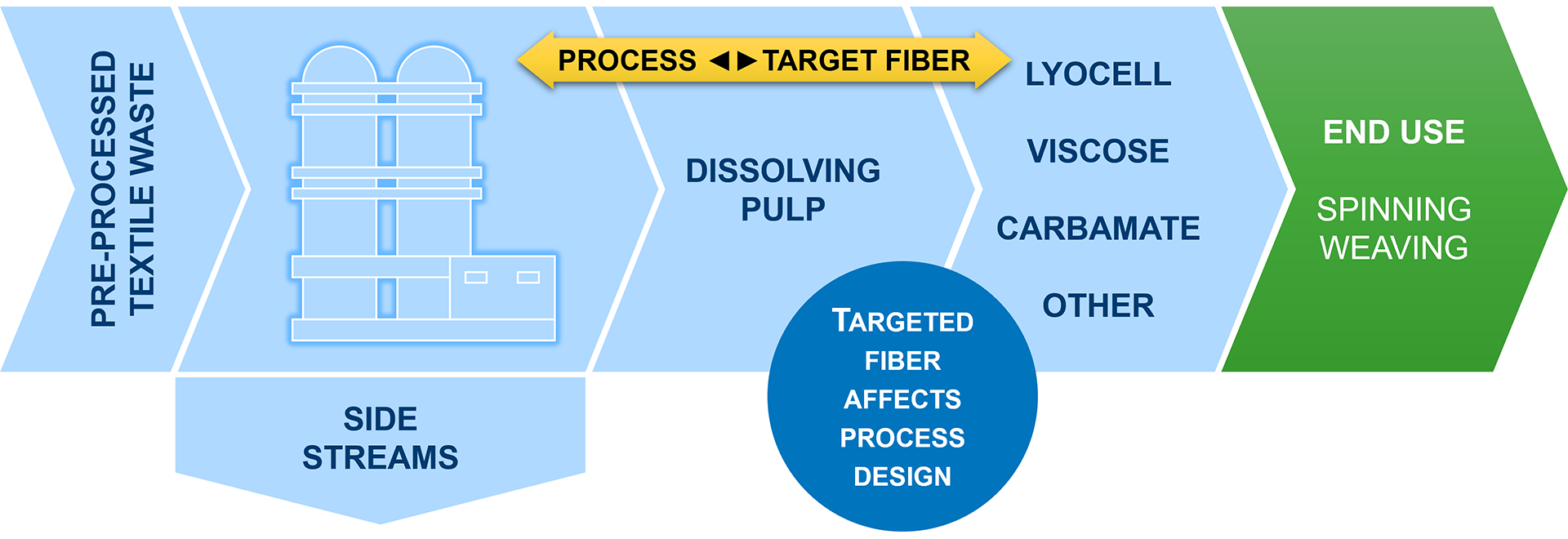

Chemical recycling is the process of recycling textile waste (such as cotton and polycotton) back into its raw fiber material form. The results can be used to produce new textiles using the same techniques as with virgin material. Because chemically recycled fibers are like virgin fibers, a recycled pair of worn-out jeans, for example, can be upcycled into another piece of clothing just as sturdy and comfortable. The specifics vary depending on the technology used, but the basic process remains the same: Textile waste (without contaminants like zippers and buttons) is treated in a chemical process which removes dyes and materials that can not be recycled. The material is modified so that it can be turned into strong fibers ready for textile production.

Chemical textile recycling process can produce many possible fiber types

TURNING IDEAS INTO REALITY

When a customer approaches us with an idea on chemical recycling, our process experts and test laboratories start working together with the customer. They test and develop the idea to see if and how it can be scaled up to capacities required for a commercially viable process. We do not compete with customers – we help them achieve their goals for our mutual benefit.

ANDRITZ has a long history of mutually productive partnerships with our customers. When you choose us as your partner in developing your chemical recycling process, you get a reliable companion with extensive and solid expertise in industrial-scale process technologies and a desire to help our customers to succeed.

Cooperation partners

In 2020 Infinited Fiber Company and ANDRITZ signed a cooperation agreement to develop the process and equipment solutions for Infinited Fiber Company’s textile fiber regeneration technology. The technology can turn any cellulose-rich raw material, including discarded textiles, used cardboard or rice/wheat straw, into Infinna™ cellulose carbamate fibers.

In 2021, the US recycling technology innovator CIRC and ANDRITZ signed a cooperation agreement to bundle each party’s expertise in the field of recycling of polycotton and to upscale CIRC’s recycling technology for commercial use.