Electrical Power Systems (EPS)

Electrical power systems provide turnkey solutions for hydropower plants, including engineering, design, and supply of electrical and balance-of-plant equipment that allows turbine and generator to operate efficiently.

EPS covers the complete range of project processes, including system engineering and project management, up to final handover to the customer.

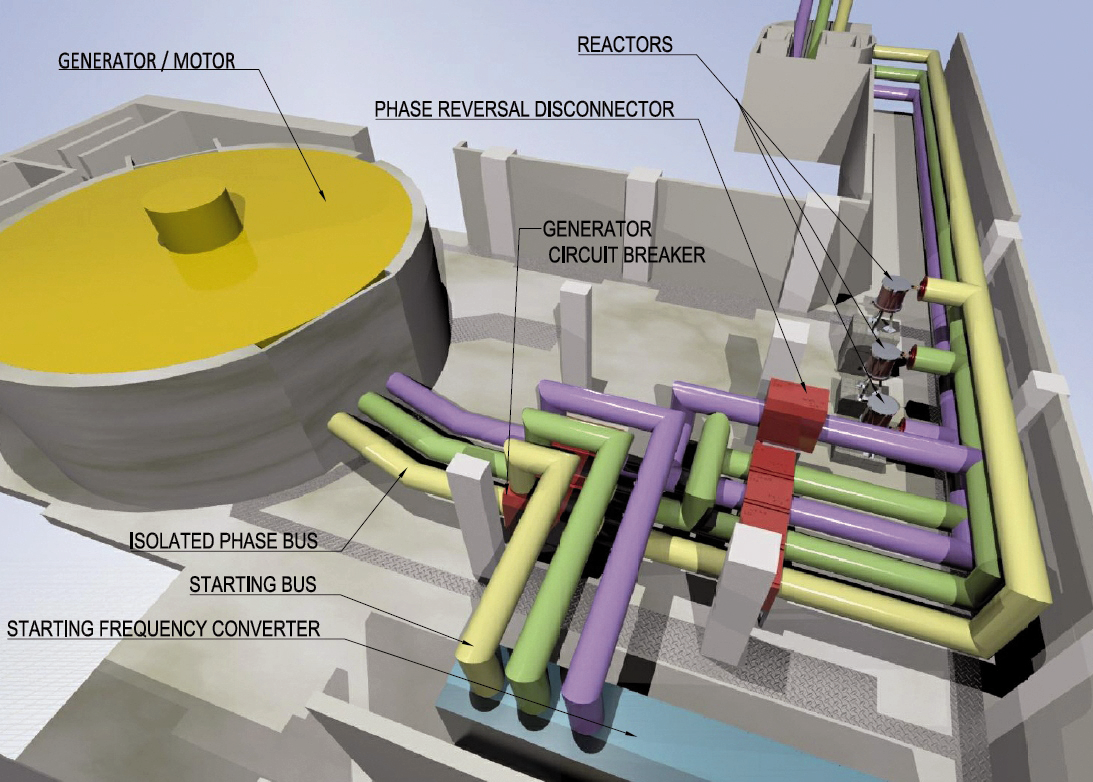

Axonometric view of generator bus duct

Assisted by its many experienced engineers, who have a long history of projects executed successfully, ANDRITZ Hydro provides the entire EPS equipment from a single source in order to guarantee that the customer receives a fully functional power plant system customized to his needs.

The equipment range includes low-voltage, medium-voltage, and high-voltage equipment for indoor and outdoor applications; power and instrument transformers; HV substations; back-up diesel generation and battery systems; grounding and lightning protection; fire-fighting and alarm systems; lighting and small power systems; the complete cabling and interconnection system up to transmission line links, as well as ventilation and air conditioning for the power plant.

All equipment will be integrated into the automation, control, and protection system of ANDRITZ Hydro, including the interface management to other auxiliary systems.

In addition, EPS provides engineered solutions of highest quality for special applications, such as pumped storage plants, by integrating starting frequency converters as well as AC excitation systems for adjustable speed plants.

The client benefits from worldwide equipment sourcing, taking account of his expectations and quality requirements.

The work will be performed according to internationally accepted standards, e.g. IEC, ANSI, IEEE, NEMA, also respecting national requirements.

Main EPS tasks

- Assisting customers in the early stages of project development to design optimal electrical solutions, also considering robustness and redundancy concepts

- Analyzing the comprehensive energy system, including compliance with governing rules and regulations, also observing grid code requirements

- Conceptual design, all required simulations, studies and calculations for defining parameters, selection of the equipment, and integrating all parts into the project

- All required documentation, such as single-line diagrams, circuit diagrams, cable schedule, and axonometric design and routing, in order to guarantee the quality and the timely implementation of the project

- Management and coordination of all internal and external interfaces by meeting the overall project time schedule

- Project management and system engineering throughout the entire project phases

- Preparation of installation and commissioning procedures

- Installation, supervision, commissioning, commissioning coordination, training of customers’ personnel, and handing over the equipment to the client - supported with as-built documentation and Operation & Maintenance manuals