Metris addIQ radar feed controller for peeler centrifuges

Improve process throughput profoundly with ANDRITZ and one of the best value-for-money radar feed control units available today.

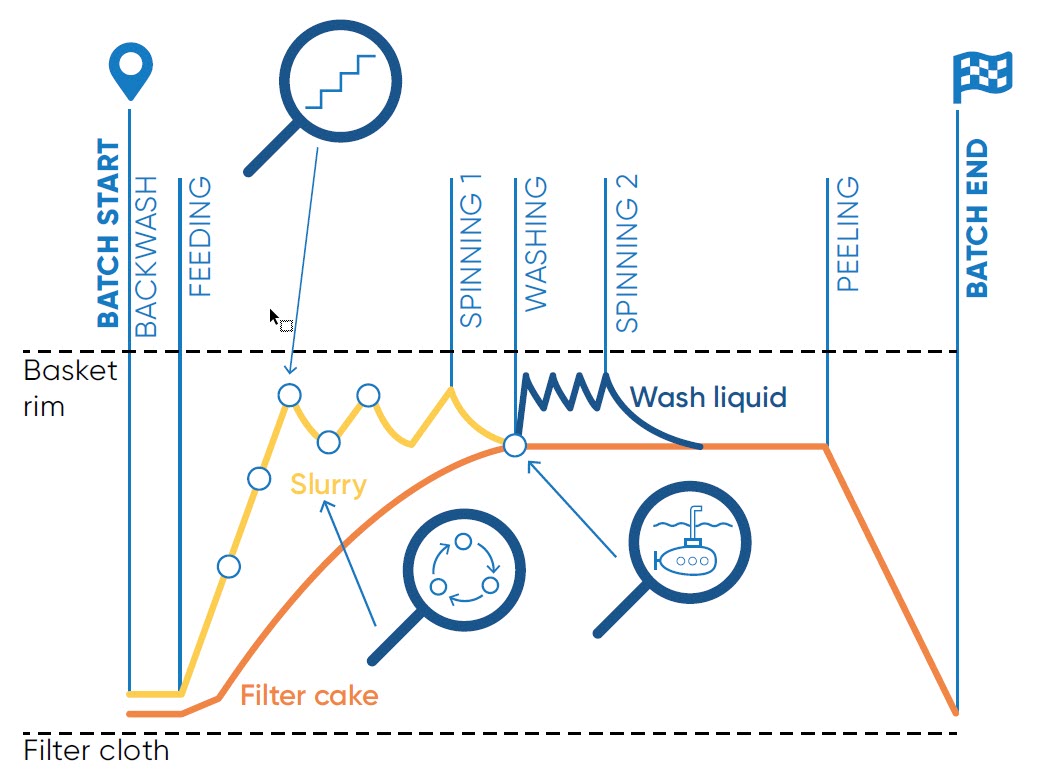

Many process industries deploy the peeler centrifuge as an efficient method to separate liquids from solids. However, the fill level within a peeler centrifuge must be carefully controlled to maximize throughput and efficiency. Filling is determined by the feed controller, a key component that ensures the ideal level is maintained as the solid cake builds up. Choosing the right feed controller can make a huge difference to operations by continually optimizing separation performance.

Realize the benefits of Metris addIQ radar feed controller

In-built precision enables an increased throughput, representing a significant operational gain for owners and operators. With a highly competitive price point, Metris addIQ radar feed controller offers real value for money on capital expenditure, but they deliver numerous operational cost benefits too.

A radar feed controller detects the fill level by emitting extremely rapid microwave pulses

Illustration of the operating principle of feed control in a peeler centrifuge

Benefits and features at a glance

- Maximum throughput

- Maximum product quality

- Maximum availability

- Multi level detection for varying product conditions

- Multi purpose for varying atmosphere conditions and product changes

- Submerging point detection to reduce time for first spinning and optimize wash effect

- Applicable for peeler centrifuges