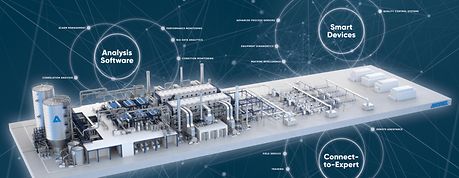

ANDRITZ pulp dewatering machines for highest production applications

ANDRITZ Twin Wire dewatering systems achieve proper sheet formation, high dryness, and high specific production at low cost.

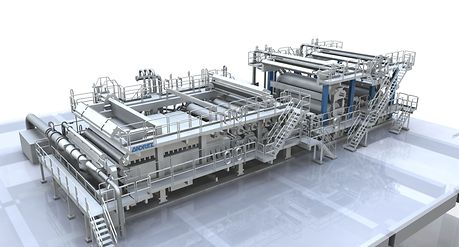

ANDRITZ Twin Wire Former pulp machine

ANDRITZ shoe press with X-nib

Components of the ANDRITZ pulp dewatering machine

- Headbox

- Twin Wire Former

- Press section

Advantages at a glance

- Step diffuser headbox for proper sheet profile and formation

- Optimum sheet formation to top and bottom side due to Twin Wire technology

- Double-sided dewatering starts directly after the headbox

- The Twin Wire Former ensures high wet sheet tensile strength for any market pulp sheet drying plant

ANDRITZ headbox – optimum sheet profile and sheet formation

Well-proven, state-of-the-art headbox technology is used in paper production as well as for pulp dewatering machines. The hydraulic flow is even and uniform due to the conical inlet header. In combination with the step diffuser, this delivers a proper sheet profile and a strong sheet.

ANDRITZ headbox advantages

- Conical shape for even hydraulic flow and homogenous pulp distribution

- Dilution profiling system (manual or automatic control) in turbulence section for high sheet profile quality

- Sheet formation and high sheet strength

- Easy maintenance (swiveling type, good accessibility)

ANDRITZ Twin Wire Former – efficient double-sided dewatering

The Twin Wire Former starts directly after the headbox, ensuring proper formation on both the top and bottom side of the sheet.

ANDRITZ Twin Wire Former advantages

- Double-sided dewatering immediately after headbox

- High capacities

- Gentle and efficient dewatering

- No vacuum applied

- No risk of sheet sealing

- Fines are distributed evenly in the sheet

- High sheet strength, optimum formation

- Reliable operation and runnability

- Heavy sheet due to high basis weight – easy to cut

ANDRITZ press section with combi and shoe press – over 50% dryness

ANDRITZ combi press advantages

- High dryness due to high design linear pressure

- Easy and fast start-up due to tail transfer system

- High ingoing dryness due to felted lump breaker

ANDRITZ shoe press with X-Nip (ANDRITZ PrimePress X) advantages

- 3–5% higher dryness than HI presses

- High dryness due to optimum pressure curve

- Long service life of press sleeves