Burners for metallurgical processes

Products for metallurgical industries are custom-designed, special burners. These burners are designed individually, according to each customer’s needs. All relevant conditions at the customer's facility for the burner equipment are evaluated thoroughly in terms of fuels, burner capacity and process issues.

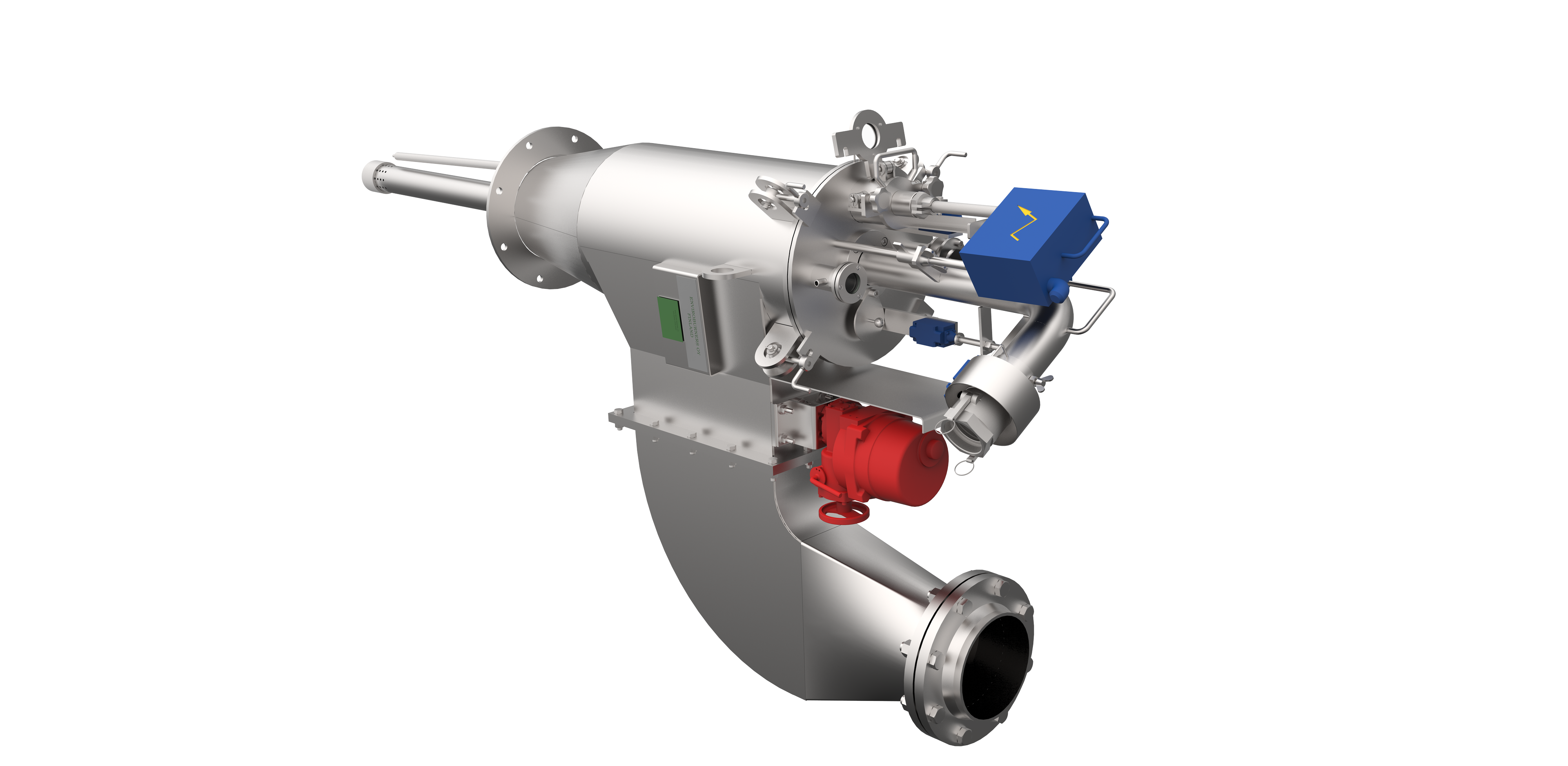

Metallurgical process burner 3D rendering

Launder and ladle burners are used for refractory heating of receiving launders and ladles at the anode furnace outlet area. These burners are manually operated, natural gas or light fuel oil burners. The structure is made of stainless steel excluding the flame cone, which is made of heat-resistant steel. The burner is self-aspirating so ambient air is used as combustion air.

Reaction shaft, settler roof and settler wall burners are used as start-up and/or auxiliary burners for a flash smelting furnace. These burners use natural gas or fuel oil with compressed air atomization. The burner structure is normally made of stainless or acid-proof steel. A combustion air damper with actuator for air control purposes is included in the burner structure.

Anode furnace burners are used for heating purposes in the copper oxidation process and for maintaining the right copper temperature during casting. The burners use natural gas or fuel oil with compressed air atomization. In the combustion air duct section. There is a shaft to enable burner twist along a furnace. A combustion air damper with actuator is included in the burner structure.

Other special burners such as hot-air generator burners, CO2 burners, preheating and start-up burners are also available for different kinds of metallurgical processes.

| Launder and ladle burners | |

| Application: | Casting launders, ladles and molds |

| Fuel: | Natural gas, light fuel oil |

| Burner capacity: | 0.25-0.5 MW |

| Operating mode: | 1-stage |

| Control range: | 2:1 |

| Atomizing medium (fuel oils): | Dry pressure air, 600 kPa (g) |

| Combustion air: | Ambient fresh air, self-aspirating |

| Ignition device: | High-energy spark igniter, 4-12 J |

| Reaction shaft, settler roof and settler wall burners | |

| Application: | Flash smelting furnace |

| Fuel: | Natural gas, light fuel oil, heavy fuel oil |

| Burner capacity: | 2-4 MW |

| Operating mode: | Single and 2-stage or modulated |

| Turndown: | 4:1 |

| Atomizing medium (fuel oils): | Dry pressure air, 600 kPa (g) |

| Combustion air: | Normal fresh air, 4-8 kPa Oxygen enrichment possible, 0-95% |

| Air/fuel ratio: | 0.9-1.1 |

| Cooling air: | If the burner is shut down and a removable center flange unit is in place, 10-15% of the combustion air supply should be left on as a source of cooling air. |

| Ignition device: | High-energy spark igniter, 4-12 J Natural gas/propane-operated igniter, 120 kW |

| Anode furnace burners | |

| Application: | Anode furnace |

| Fuel: | Natural gas, light fuel oil |

| Burner capacity: | 5-10 MW |

| Operating mode: | Modulated |

| Turndown: | 4:1 |

| Atomizing medium (fuel oils): | Dry pressure air, 600 kPa (g) |

| Combustion air: | Normal fresh air, 48 kPa Oxygen enrichment possible, 0-30% |

| Air/fuel ratio: | 0.9-1.1 |

| Cooling air: | If the burner is shut down, 10-15% of the combustion air supply should be left on as a source of cooling air. |

| Ignition device: | High-energy spark igniter, 4-12 J Natural gas/propane-operated igniter, 120 kW |