CLEAR ADVANTAGES OF DISPLACEMENT WASHING

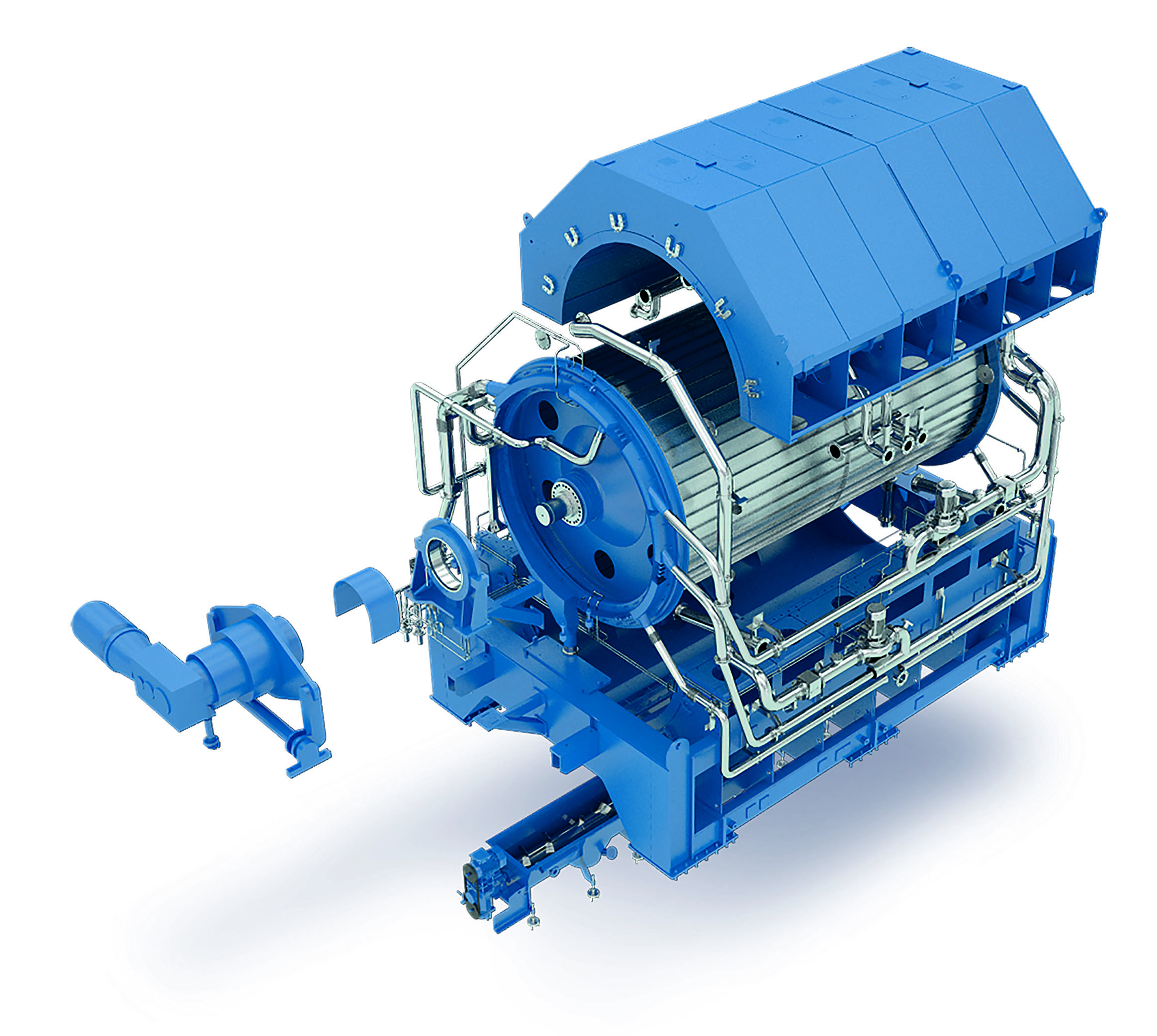

In the early days, almost all mills had vacuum drum filter washers. The main disadvantage was the amount of serial equipment to reach a certain wash result and a limited process temperature. Following this, wash presses were introduced. The main disadvantage was the requirement to dilute and then mechanically press the pulp several times to reach a desired high consistency. The DD-Washer performs all washing stages in a single rotating drum and roughly at the same consistency without dilution. Since there is no mechanical pressing during washing, the DD-Washer is extremely gentle, retaining all the bulk, stiffness, and strength of the original fibers.