Meet ANDRITZ Nonwoven & Textile all over the world

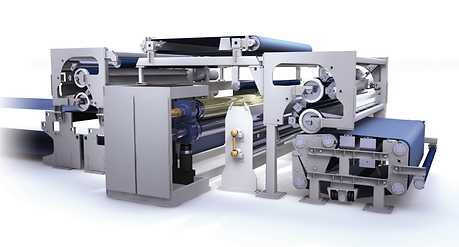

Spunjet: the direct way from polymer

Spunjet technology produces a new generation of nonwovens with superior properties such as bulk, softness, drape, and tensile strength.

Integrated technology: Spunjet and thermobonding

Bonding solution for filaments

ANDRITZ's expertise in the nonwovens industry gave birth to Spunjet - combining the strength of spunlaid with the softness of spunlace. This inline hydroentanglement of continuous filaments creates a new generation of spunlaid nonwovens.

Spunjet nonwovens fabrics have unique properties:

- 25-30% higher tensile strength

- 50-75% higher tear strength

- 50-80% more bulk

A unique configuration

While creating a new generation of products, this innovative Spunjet process offers a 3-in-1 configuration with the opportunity to combine Spunjet with a thermobonding calender from ANDRITZ Küsters in the same line. Depending on the desired properties of the nonwovens product, the line can utilize thermal bonding, conventional spunbond, and/or hydroentanglement, Spunjet, or even both in the case of Spunjet Soft.

Spunjet lines can operate at speeds of up to 1,000 m/min. Different nonwoven fabric properties are attainable depending on the Spunjet configuration.

Spunjet Bond

Spunjet Bond is an inline hydroentanglement process using spunlaid filaments which is ideal for producing nonwovens rolls for geotextile applications.

Spunjet Splittable

Spunjet Splittable performs the splitting and hydroentanglement of spunlaid bi-component filaments, which can open new business opportunities in technical fabrics such as hot gas filtration materials.