Meet ANDRITZ Nonwoven & Textile all over the world

Spunjet Soft produces softer fabrics

Spunbond producers now have the opportunity to combine first-class thermal bonding and efficient jet water treatment in order to add value to their end products

Finishing solutions for filaments

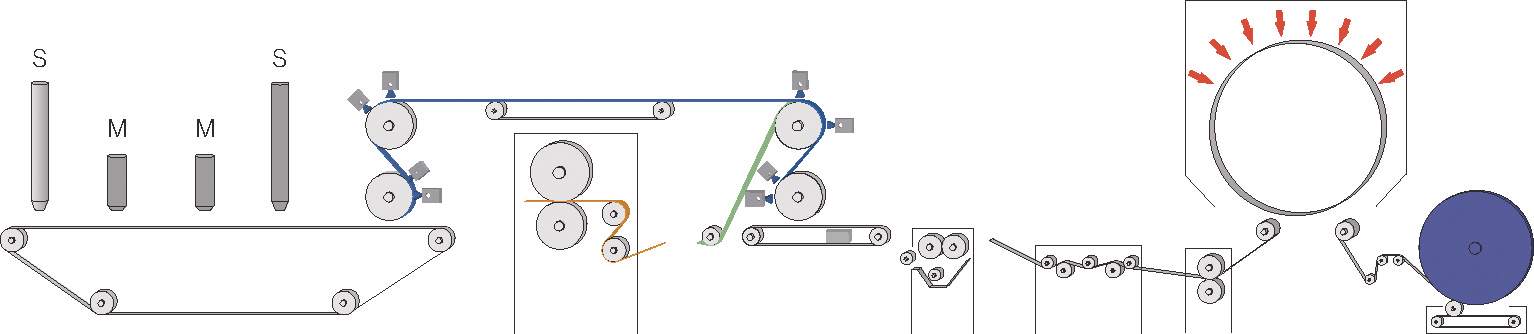

The innovative spunjet process is the result of ANDRITZ Nonwoven’s expertise in the nonwovens industry. Spunjet creates a new generation of spunlaid nonwovens through the inline hydroentanglement of continuous filaments or spunbond webs.

Spunjet Soft expands the range of spunbond technology to offer manufacturers greater flexibility with unique softness properties and new functions to the basic web.

Medium hydraulic energy is applied by one or two injectors. This softens the surface of calendered spunbond nonwovens. By changing jets, pressure, or entanglement support, various effects and grades can be produced.

New characteristics for hygiene products

This jet finishing results in unique product properties:

- Lower bending modulus and better drapability

- 50 to 80% more bulk

- Effective range: 15 to 150 gsm

- Speed up to 1,000 m/min

Easy to implement

Spunjet Soft is perfectly designed for the spunlaid process in terms of speed and runnability. The hydroentanglement system can also be implemented on existing spunbond lines matching the operating speed of the most recent multi-beam spunbond machines. This new generation of spunjet is available with a working width up to 6 m.