Feed and biofuel technologies products in China

ANDRITZ Feed and Biofuel Technologies mainly provide the following products:

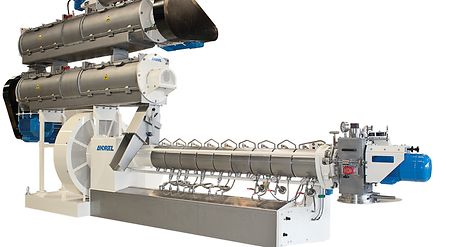

Main product-Extruders

ANDRITZ FEED & BIOFUEL extruder uses advanced technology to ensure unique quality feed at minimum operating costs.

Our advantage:

- High pressure, high shear force, and high cooking ability to produce feed of premium quality;

- The cutting knife system can adjust the precision-adjustment device of the blade and the die ring to ensure the consistency of the product length;

- Equipped with a precision metering device for addition of water and other liquids, effectively ensuring uniform moisture content in the product;

- Equipped with monitoring components for the temperature, pressure, and the amount of steam and water added, which can realize online monitoring of production parameters to facilitate operation.

Expansion Control System ECS

ANDRITZ-patented product and a reliable system for accurate control of expansion/density.

Our advantage:

- Reduces expansion

- Improves the sensory and physical properties of the products

- Fewer demands on raw material quality

- Decreases the amount of water added during the extrusion period

- Increases capacity by 25-50%

- Produces 100% sinking feed and slow-sinking feed

Dryer: Suitable for aquatic feed and the pet food industry

Extruder: Suitable for aquatic feed and the pet food industry

Main product-Dryers:

Our advantages:

- Accurate flame control: 1-30 times the flame length;

- Focuses on safety: A control system of fully enclosed independent ignition controller and separate transmission of natural gas and air to ensure safety and stability;

- High efficiency and energy saving: The burner's combustion efficiency is close to 100%.

The energy saving effect of ANDRITZ dryer is remarkable. Due to the high efficiency of the dryer and the smaller dimensions than other equipment with the same capacity, a lot of investment at the early stage and production costs can be saved based on the conditions of the capacity and civil works. Moreover, the moisture uniformity of the dryer is also advanced, which is very helpful for ensuring the safe moisture of the finished products without excessive drying.

Main product-Vacuum Coaters:

Our advantages:

- With high manufacturing accuracy and imported key components, our vacuum coaters feature high oil injection ratio and uniform spraying;

- The pellet breakage rate is lower than one-tenth of other similar products.

Twin Screw Extruders:

Our advantages:

- Safe and high reliability;

- Easy to clean and maintain;

- Screw self-cleaning;

- Good formula adaptability (high fat, low starch);

- Reduces internal residues and the risk of die ring clogging.