“There is so much valuable organic material around that we are not using at all or not using fully. I find it exciting and extremely important to help make some progress here.”

Thomas Wünsche, Industry Director, Food & Beverage

How to feed 9.7 billion people?

Alternative proteins, food waste and ANDRITZ Separation

“The world’s population is projected to reach 9.7 billion in 2050 from 7.9 billion today. One of our greatest challenges will be to feed these extra people with adequate, safe, sustainable, and nutritious food that is produced, consumed and disposed of in a way that safeguards our precious natural ecosystems,” stated the UN’s Food and Agricultural Organization (FAO) in a news post last December. The FAO mentions the trend towards alternative proteins as one of the most promising developments in this context, due to the opportunities to partially substitute for proteins coming from unsustainable agri-food practices such as intensive livestock farming or overfishing.

According to the FAO, alternative proteins include microbial proteins such as microalgae, insect-based proteins, cell-based meat, and plant-based meat substitutes. ANDRITZ Separation is responding to this trend, for example with solutions to extract protein from peas. The protein can be used in plant-based meat substitutes or to enrich various food products. It is easy to store and handle. But this is just one part of the story.

Making better use of resources

Separation recently introduced an entirely new technology that extracts even more valuable substances – such as proteins, polyphenols or dietary fibers – from organic material, especially side streams in food processing.

“There is so much valuable organic material around that we are not using at all or not using fully. I find it exciting and extremely important to help make some progress here,” says Thomas Wünsche, Industry Director for Food & Beverage in Separation. “Take orange peel, for example. First, the food industry only used the juice and disposed of the peel. Then they extracted oils from the peel, after that pectin, then proteins and polyphenols, and now even dietary fibers are extracted and used. That’s exactly what we should do to reduce food loss and move towards a circular economy. In addition, we should look at resources that have not been considered at all so far.

Just think of the olive leaves that are part of the olive harvest. They contain ten times as much polyphenol as the olives. The list of examples and opportunities is endless.”

Driven by environmental requirements and changing consumer trends towards healthier, more ethical diets, such alternative proteins and valorization of side streams have become megatrends in the food processing market, which is the #1 business sector worldwide.

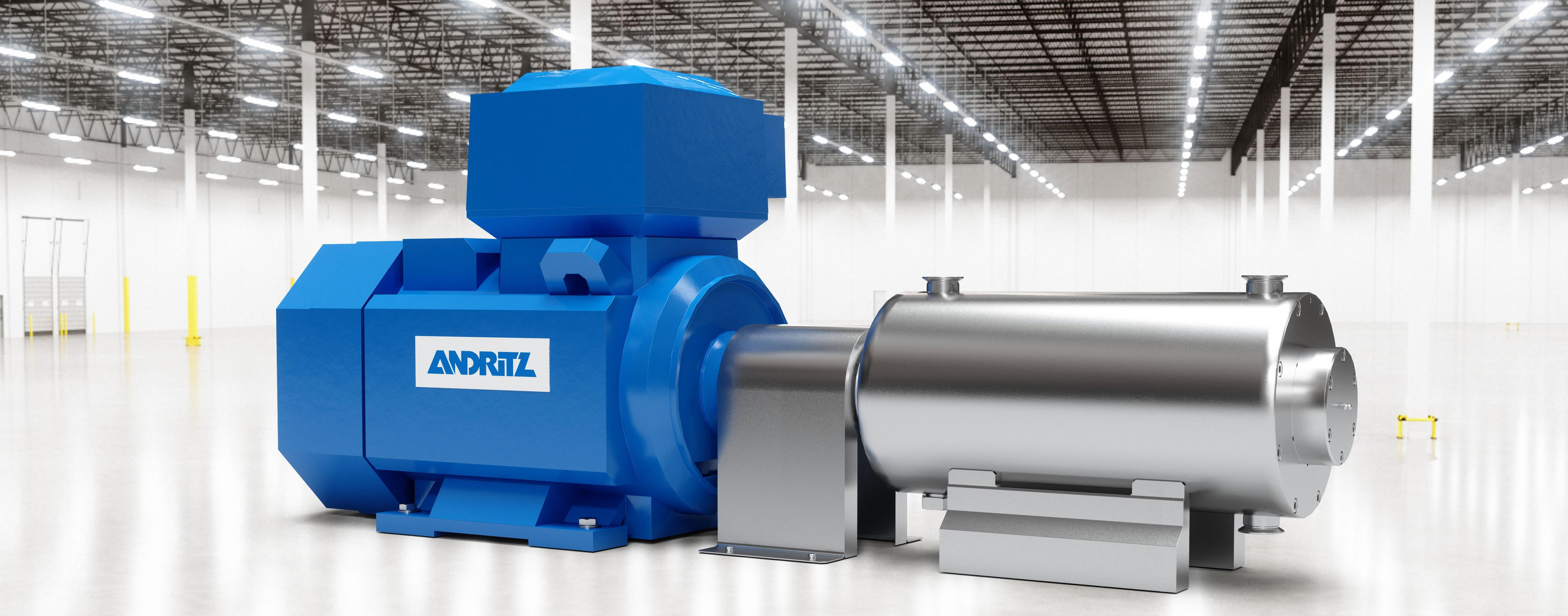

The newly developed Turbex extractor is at the heart of Separation’s related activities. Having completed testing on a prototype in Vierkirchen, Germany, Separation introduced it to the market in January, raising considerable interest. With a proprietary patented technology, it is designed to achieve a higher yield and consume less energy than conventional extractors. “We see our Turbex as an enabler to make the most of the valuable food resources we have,” says Wünsche.

Turbex, patented solid/liquid extractor for disruptive extraction processes

Valorization center in progress

Given the strategic importance of the topic, Separation is building a valorization center at the Gouda location in the Netherlands. “We will have a Turbex there as well as our various machines that can be installed downstream and upstream to create a complete line – our grinding mills, decanters, filters and dryers. Customers will be able to try out different configurations and test new organic materials. There is a multitude of new ideas for materials waiting to be explored,” Wünsche says. The new center will open in the second quarter of 2023.

Considering the food market’s dimensions, Separation has selected some promising niches to focus on.

In addition to pea proteins, they include protein from spent grain (a byproduct of the brewing industry with a very high protein content), and extracts from botanicals (roots, flowers, bark and leaves) used, for instance, in nutraceuticals and bakery products.

Interestingly, the feed market is showing trends similar to those of the food sector. Producers of feed for fish and chicken farms, for instance, have started using alternative proteins. Separation and Feed & Biofuel work together whenever they see opportunities to combine their knowledge and product portfolios.