ANDRITZ front-end package for wood-based MDF production

- Wood processing technology

- Chip storage

- Chip washing with wash water cleaning

- Pressurized refining system

- Waste water evaporation

ANDRITZ systems for fiberboard plants are based upon many years of experience in the design and manufacture of production machinery.

Complete front-end system

ANDRITZ Panelboard - complete lines, components and service

ANDRITZ Panelboard supplies innovative single equipment and complete front-end packages, ranging from debarking, chipping and screening, to chip handling, as well as from chip washing to pressurized refining systems, including waste water evaporation. Our machines process any species of wood or annual fibers, such as bagasse, bamboo or straw. Extensive system and process know-how for panelboard fiber preparation is the technological basis of our solution, which also comprises responsive service, replacement parts, and upgrades to existing machines. Low electrical and thermal energy consumption with best performance is the driving factor for the design of each individual machine in the system and the process.

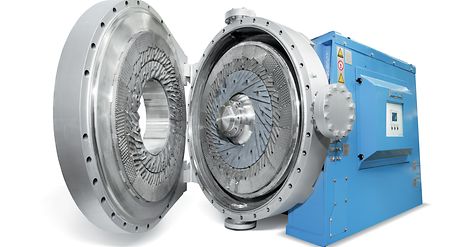

The trust of our customers is confirmed by more than 320 successfully installed pressurized refining systems around the world. Top performance, high reliability, and excellent availability are hallmarks of the ANDRITZ high-consistency refiners, which ensure trouble-free operation and ease of maintenance, even in demanding applications such as processing veneer chips, shavings, sawdust, and waste wood. The innovative “swing-door” design of our refiners makes it easy and quick to change refiner plates. With the addition of the latest process control and plant instrumentation, our customers receive a complete, highly sophisticated front-end system, all from a single source.

High-consistency refiner 1CP

Next-generation performance: Innovative production technologies deliver benefits today

The future has arrived. Forward-thinking panelboard producers are taking advantage of innovative new features on new systems that can also be retrofitted to existing equipment. Innovations in thermal and electrical energy savings, IIoT connectivity, and smart-plant networks are part of ANDRITZ’s offering for new front-end systems.

Guangxi Chongzuo Lelin Forestry Development Company has started up the world’s largest chip washing and pressurized refining system, supplied by ANDRITZ. For more information about this giant project download our brochure.

We need to reduce the energy our buildings consume to combat climate change. ANDRITZ and naturheld have therefore pushed the sustainability and technical boundaries in wood-based insulation. For more information click here.

Vienna, Austria

Phone: +43 (0)50805 – 0

E-mail: panelboard@andritz.com