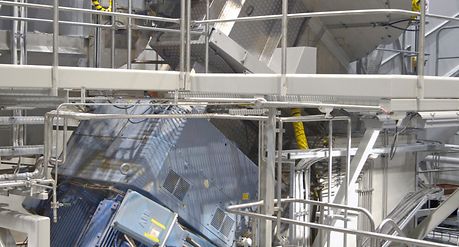

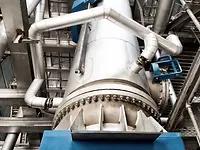

1. Wood processing

Fiberboard quality begins in the woodyard

The production of high-quality fiberboard depends upon the quality of the fiber entering the process. ANDRITZ is recognized as a leading global supplier of wood processing technology and processes: from the receiving of logs or chips through the subsequent processes of debarking, chipping, screening, storage, reclaiming, and conveying.