ANDRITZ supplies the complete package ranging from debarking, chipping, screening, washing and refining

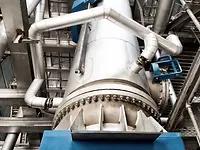

Digester for annual plants

ANDRITZ is the leading supplier of pressurized refining systems and equipment to the global panelboard industry.

To produce high-quality fiber, it is essential to treat the raw material with respect to its unique properties. The internal bond strength of the material must be reduced before the material is processed in the refiner. This is a fundamental rule to ensure uniform fiber quality.

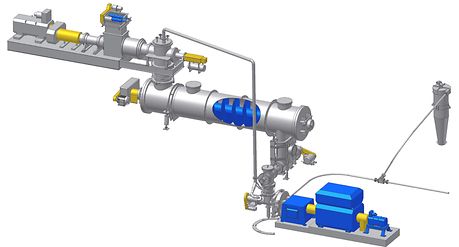

Horizontal digester with refiner

In order to soften the raw material and weaken the internal bonds, the material is heated to a weakening point. ANDRITZ offers digester systems to heat and prepare the raw material. Basically, two types of digester systems are used (vertical and horizontal). Both systems are heated with pressurized steam and operate under pressure.

The vertical digesting system is preferable for materials with good transportation behavior (e.g. wood chips).

The horizontal digesting system is better for materials with poor transportation behavior (e.g. most annual plants). The feedstock is fed continuously through the digester by a conveyor screw in a horizontal tube to ensure constant residence time and even heating of the material. The horizontal design prevents material bridging and the formation of dead zones in the digester.