More information about ANDRITZ solid biofuel solutions

Steam-Ex process equipment for biomass pretreatment

ANDRITZ’s Steam-Ex process equipment uses steam explosion to transform lignocellulosic biomass into various biofuels and biochemicals. ANDRITZ offers a full range of services, from engineering and equipment supply to installation and start-up of complete lines including ongoing service support.

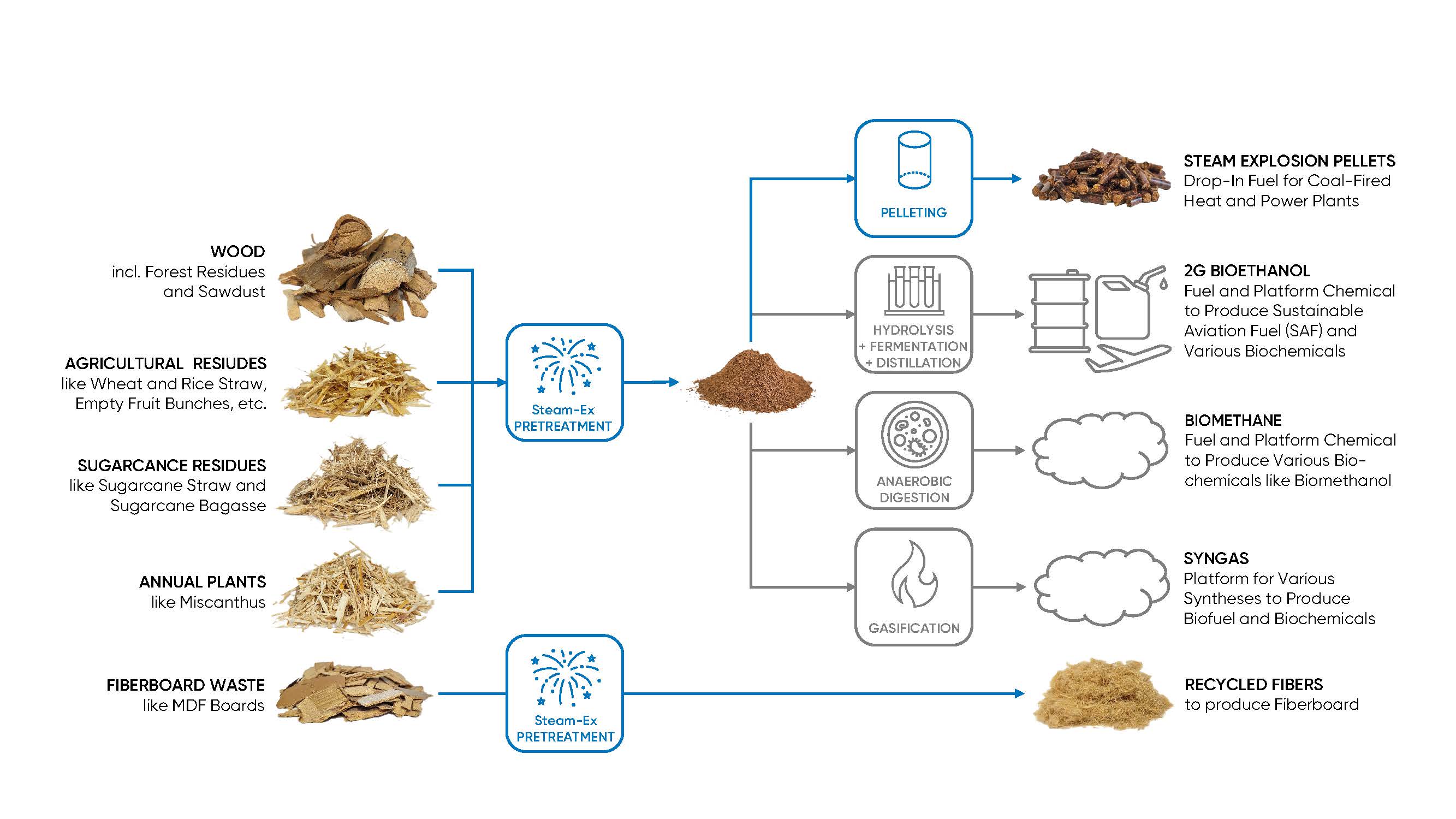

Lignocellulosic biomass – including wood, agricultural residues such as cereal straws and bagasse, and various annual plants – serves as the raw material for the Steam-Ex pretreatment process. The Steam-Ex process equipment is based on the well-established ANDRITZ equipment for the pulp and paper as well as the panelboard industries.

The final product depends on the intended use. One option is to produce a powder that can be pelletized. The resulting steam explosion pellets, also known as black pellets or advanced solid biofuels, have various advantages over conventional wood pellets, such as higher energy density, durability, and water resistance. That means they can be stored outdoors and reduces both CapEx and OpEx in fuel logistics. The biggest benefit: they entirely replace coal without requiring major investments in existing power plants.

Besides steam explosion pellets, the pretreated biomass can also be used as platform for further processes like fermentation and gasification to produce advanced liquid biofuels such as second-generation bioethanol (2G bioethanol), sustainable aviation fuels (SAFs) and various biochemicals. Additionally, some biochemicals are generated as by-products during the pretreatment process.

These advanced biofuels not only improve the performance and sustainability of biomass energy but also play a critical role in reducing carbon emissions and mitigating climate change. As a leader in the green transition, ANDRITZ is committed to providing innovative solutions and equipment for the production and utilization of advanced biofuels, ensuring a cleaner and more sustainable energy future.

Get in touch

If you have any questions or want to learn more about our capabilities, feel free to contact one of our ANDRITZ experts for biomass pretreatment.