Is this the very best showcase of sustainability at an integrated pulp and paper mill?

CircleToZero* -TOWARDS ZERO EMISSIONS AND ZERO WASTE

Opportunities for elimination, reduction, and re-use in and outside the mill:

Gaseous side streams | CircleToZero opportunities |

Nitrogen oxides | NOx reduction technologies |

Sulfur dioxide | SO2 removal technologies |

Odorous gases | Odorous gas handling and treatment |

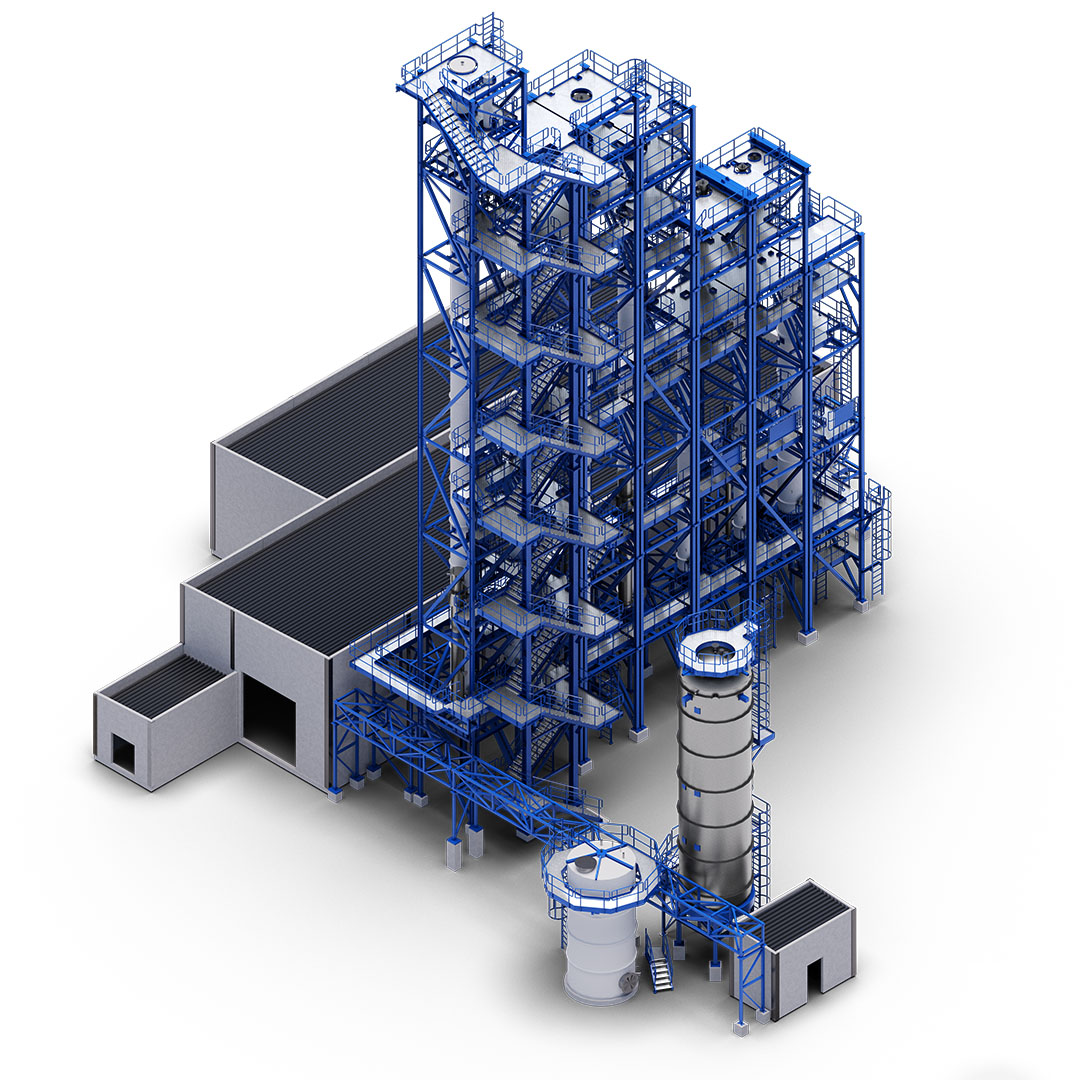

Carbon dioxide | BioCO2 utilization with hydrogen to produce biomethanol |

Solid side streams | CircleToZero opportunities |

Dregs and Grits | Source of alkali Conversion into fertilizers by removing hazardous components |

Sludge | Conversion into pellets New product development |

Ash and Gasifier bottom ash | Purification and re-use outside the mill Gasifier bottom ash as new raw material |

Lime mud | Purification and re-use Source of alkali |

Liquid side streams | CircleToZero opportunities |

Filtrates | New strategies to handle filtrates Recirculation of purified filtrates Reduced fresh water usage that is aiming towards Zero liquid discharge mill |

Raw methanol | Purification and re-use in and outside the mill New revenue generation |

Condensates | Re-use of condensates Fresh water usage reduction |

Sulfate rich streams | Extraction of sulfate to reduce the fresh water usage |

Crude Sulfate turpentine | Purification and re-use outside the mill New revenue generation |

* Trademark of the ANDRITZ GROUP. For information regarding ownership and countries of registration, please visit www.andritz.com/trademarks