ANDRITZ was inspired to take a fresh look at how to achieve this goal given that, over the years, many of the chemical “loops” have been closed to reduce emissions and effluents.

These loop closures have often been accompanied by build-ups of certain chemicals and the creation of side-streams and waste-streams that are either ignored or disposed of. Some of these side-streams represent an opportunity to generate revenue, as they contain potentially valuable raw materials for commercial-grade bioproducts if they are processed.

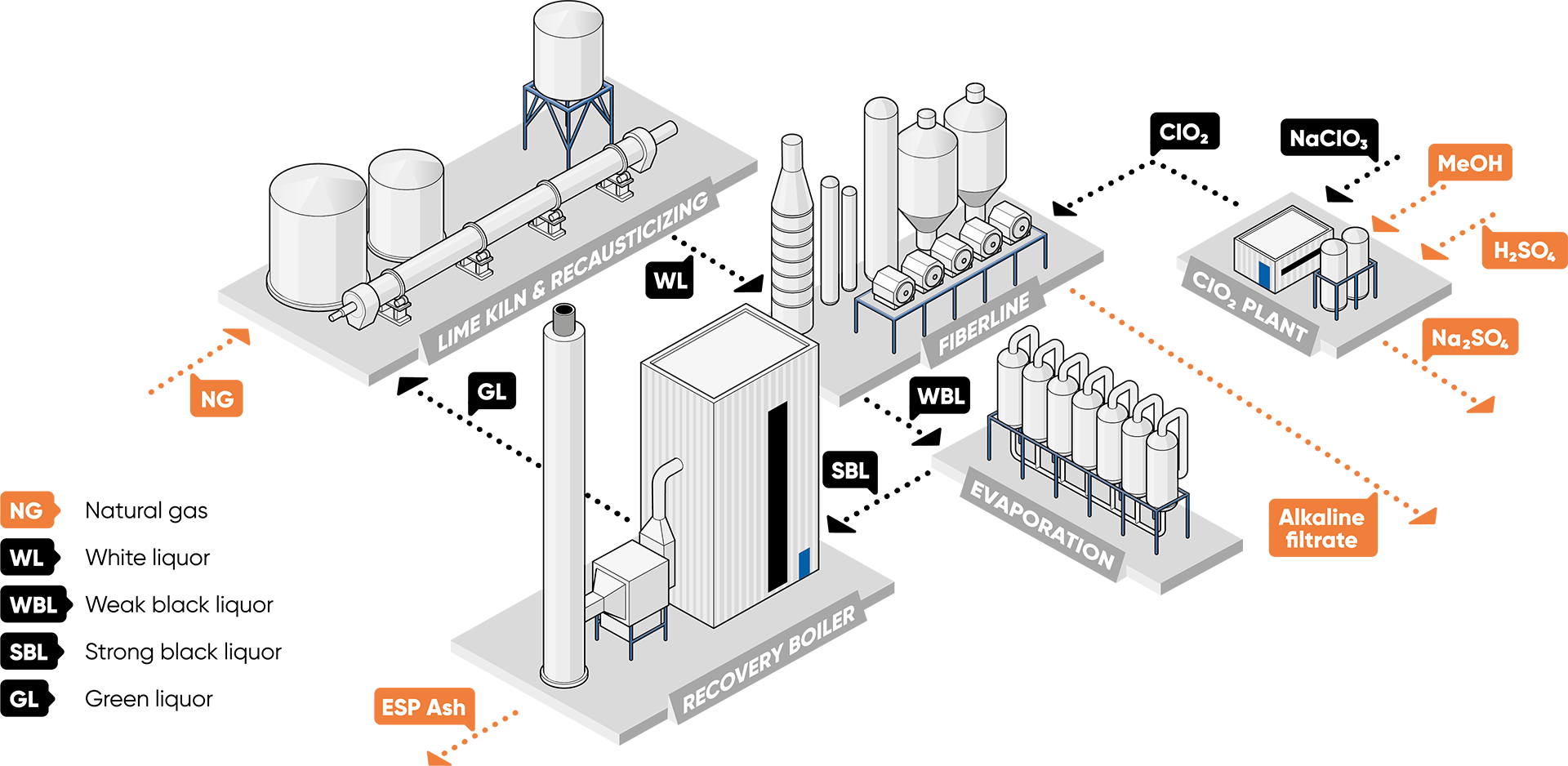

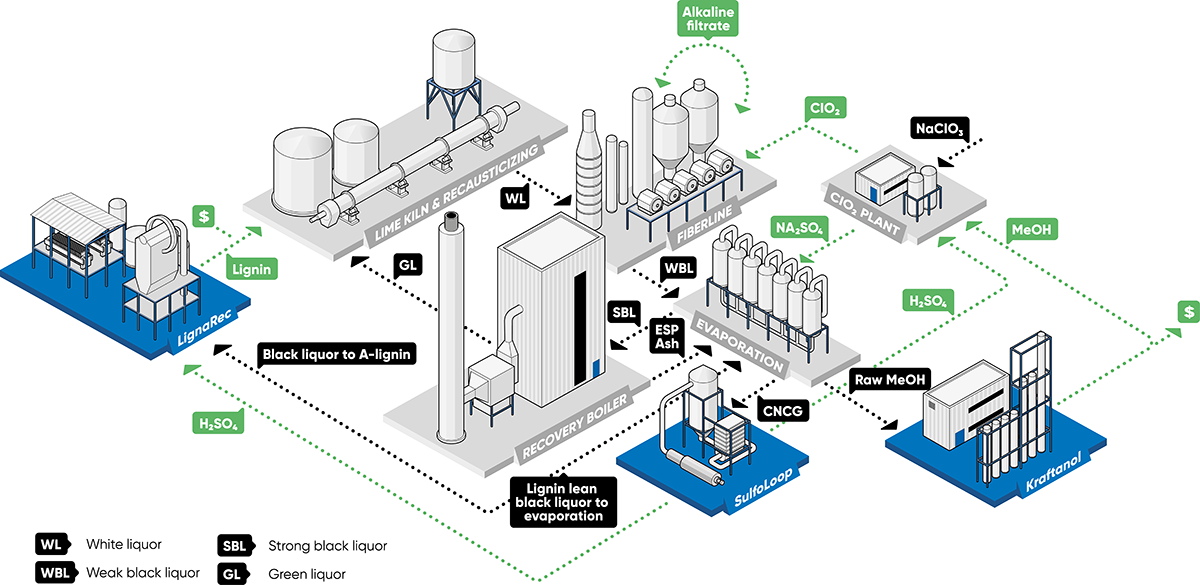

These challenges set the stage for innovation – and ANDRITZ took the lead by shining a new light on the chemical cycle. The result is a technical solution called ANDRITZ chemical recovery concept. A tailored chemical recovery system that optimizes chemical balances in a mill to increase its ability to generate additional revenue and to avoid the cost of certain purchased make-up chemicals.

Chemical recovery concept generates economic value from the side-streams in kraft pulping by:

- Purifying raw methanol to commercial quality biomethanol

- Producing commercial quality sulfuric acid on-site from concentrated non-condensable gases

- Recovering high-quality lignin from black liquor