ANDRITZ AUTOMATION

Austria

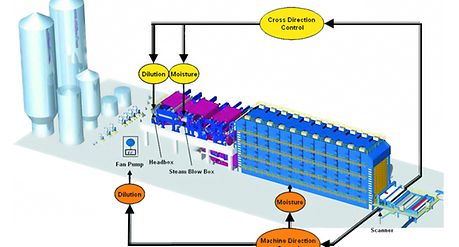

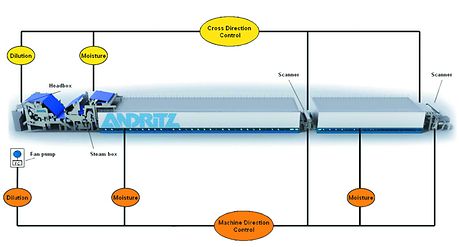

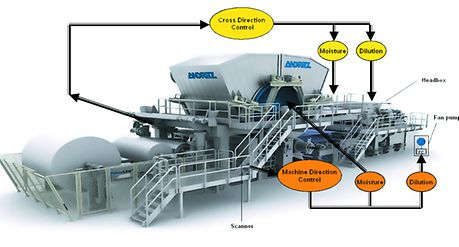

The QCS is a smart processing center for processing information and delivering reliable and precise measurements of sheet parameters, for example basis weight, moisture, temperature or brightness out of the dryer. Data from the scanner is processed and used for the cross and machine direction control.

A general overview of QCS

The QCS consists of several measuring sensors, namely a basis weight sensor, a microwave moisture sensor, a precision color sensor and a sheet temperature sensor.

The QCS for paper board machines

The QCS for tissue machines