More stories of interest around the nonwoven business

Automation of sorting revolutionizes textile recycling

Innovative automated sorting solution to achieve circularity on the textile industry.

Textile recycling in Europe is now evolving with a sense of urgency as it becomes clear that the discarding of clothing garments and apparel represents a major threat to the environment. New government regulations in Europe mean that the whole fashion and clothing industry has to completely rethink how textiles are managed at end-of-life.

From rags to riches: Textile recycling enters a new era

It is estimated that around 7.5 million tons of textiles are discarded in Europe every year. Currently only 2.2 tons are collected, with the rest going to landfill or incineration. Due to new regulations, the volume of textiles collected is estimated to rise by 4.5 – 7.2 million tons by 2030. (Source: Scaling Textile Recycling in Europe - turning waste into value, McKinsey, June 2022.)

“The new regulations mean that by 2025, all European countries will no longer be able to dispense of clothing by landfill or burning,” says Alexandre Butté, General

Manager, ANDRITZ Laroche. “All of these countries will have to have collection systems in place by that time.”

Addressing the challenges

Nouvelles Fibres Textiles was formed by two seasoned entrepreneurs in the textile industry in France, Eric Boel, who is General Director, Les Tissages de Charlieu (LTC), and Etienne Wiroth, who is General Director, Synergies TLC. Both companies are specialists in their areas, with LTC being a “living heritage” in the weaving of textiles for clothes and bags. LTC is a specialist in the automation of the weaving production process and has long experience in the use of recycled textile raw material.

A project of 4 french musketeers to the world: Nouvelles Fibres Textiles, Les Tissages de Charlieu, Pellenc ST and ANDRITZ Laroche

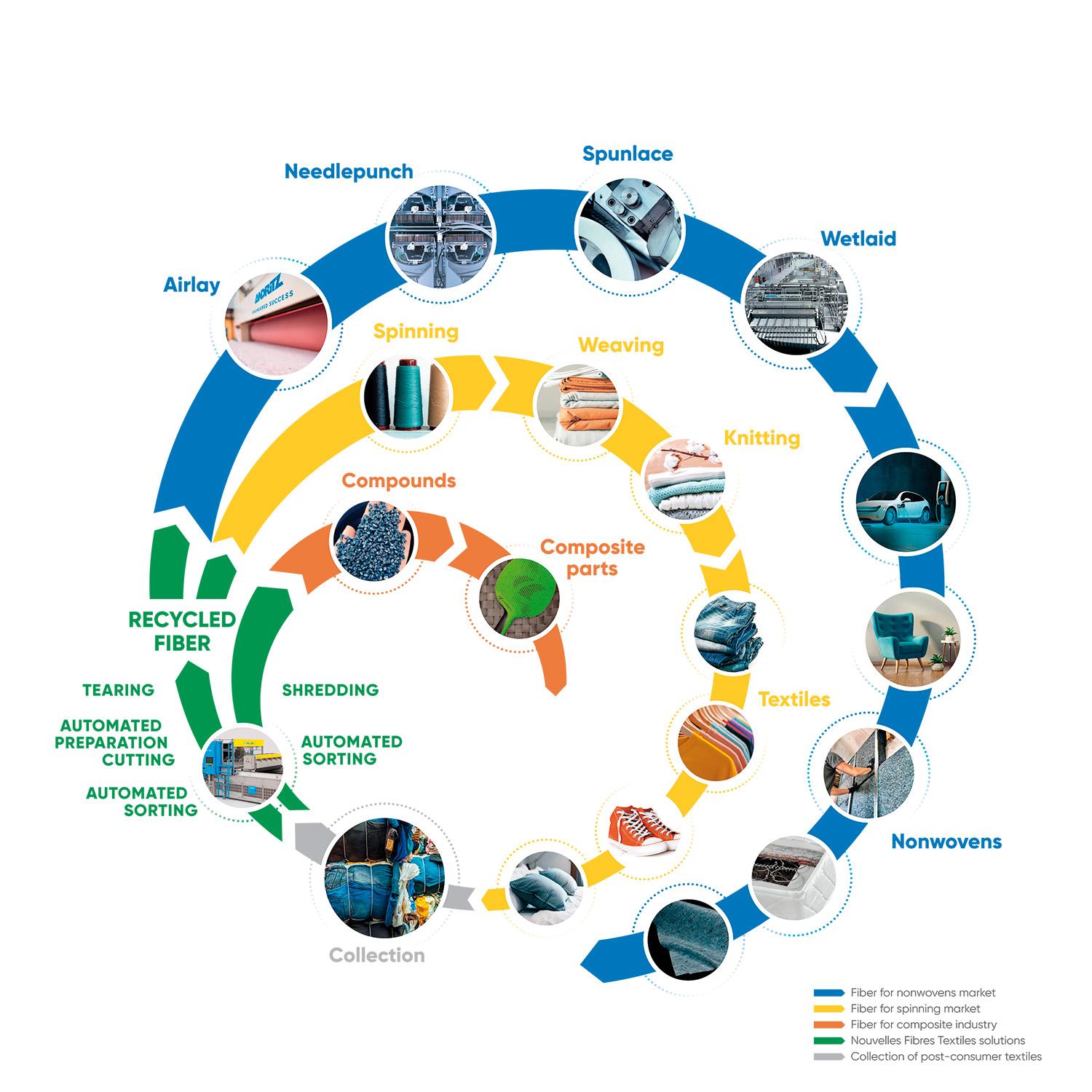

Synergies TLC focuses on collected textile sorting and is involved in numerous research and innovation projects aimed at optimizing the sorting process of used textiles. “The goal with Nouvelles Fibres Textiles is to trigger the circular economy at an industrial scale when it comes to the sorting and recycling of textiles in France,” explains Boel. “The technology used in the new demonstration plant, supplied by our partners, ANDRITZ and Pellenc ST, represents the missing link to the industrialization of textile recycling.” Wiroth adds, “Up until now we have been exporting 50% of our recovered textiles to countries such as Pakistan and India. This is because in France we haven’t yet had the technology to economically sort collected textiles by composition and color. This new automated approach to sorting will make all the difference to the recycling of textiles in France.”

WASTE SORTING MACHINES: Clips sorted by color to be processed

Nouvelles fibres textiles‘ circular and sustainable ecosystem

Textile sorting: A mammoth task for all partners

This sorting is a demanding task, simply because of the range of composition, colors, and sizes involved. Nouvelles Fibres Textiles decided to take on this mammoth task, but it needed help; this is where ANDRITZ, with its vast experience in the textile recycling industry and the building of complete manufacturing lines, joined the challenge, together with the specialist provider of waste sorting machines, Pellenc ST. All four companies are now in partnership on the project that will see the line running on 60% commercial operations with 40% of time set aside for R&D.

Concentrated expertise gives the customer the advantage

“This truly is an equal partnership between four specialist companies,” says Butté. “First of all, we have the expertise in collecting and manual sorting from Synergies followed by Les Tissages de Charlieu and its long experience and knowhow in weaving yarns made out of recycled fibers. Then ANDRITZ comes in with its deep knowledge of providing technology and complete lines for textile recycling and production. The loop is then completed by Pellenc ST and its dedicated high-tech machines purpose-built for the sorting of textiles.”