Up to 100,000 t/a

Capacity of production

Nonwoven end products based on glass fibers have a huge market and can be found almost everywhere – in ceiling tiles, cushion vinyl flooring, insulation, wallpapers, and surfaces, geotextiles, batteries, and of course roofing materials, as well as in many other applications.

Capacity of production

Line speed

Line width

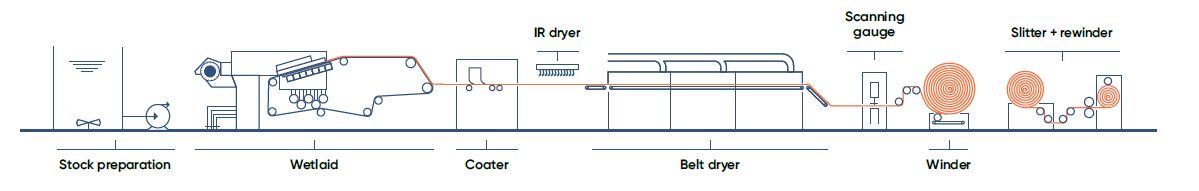

Fibers and water are mixed in the correct proportions.

The suspension is distributed homogeneously over the full forming width.

The wetlaced fabric is dried and batched.

ANDRITZ Wetlaid for glass fiber composite products, line configuration example