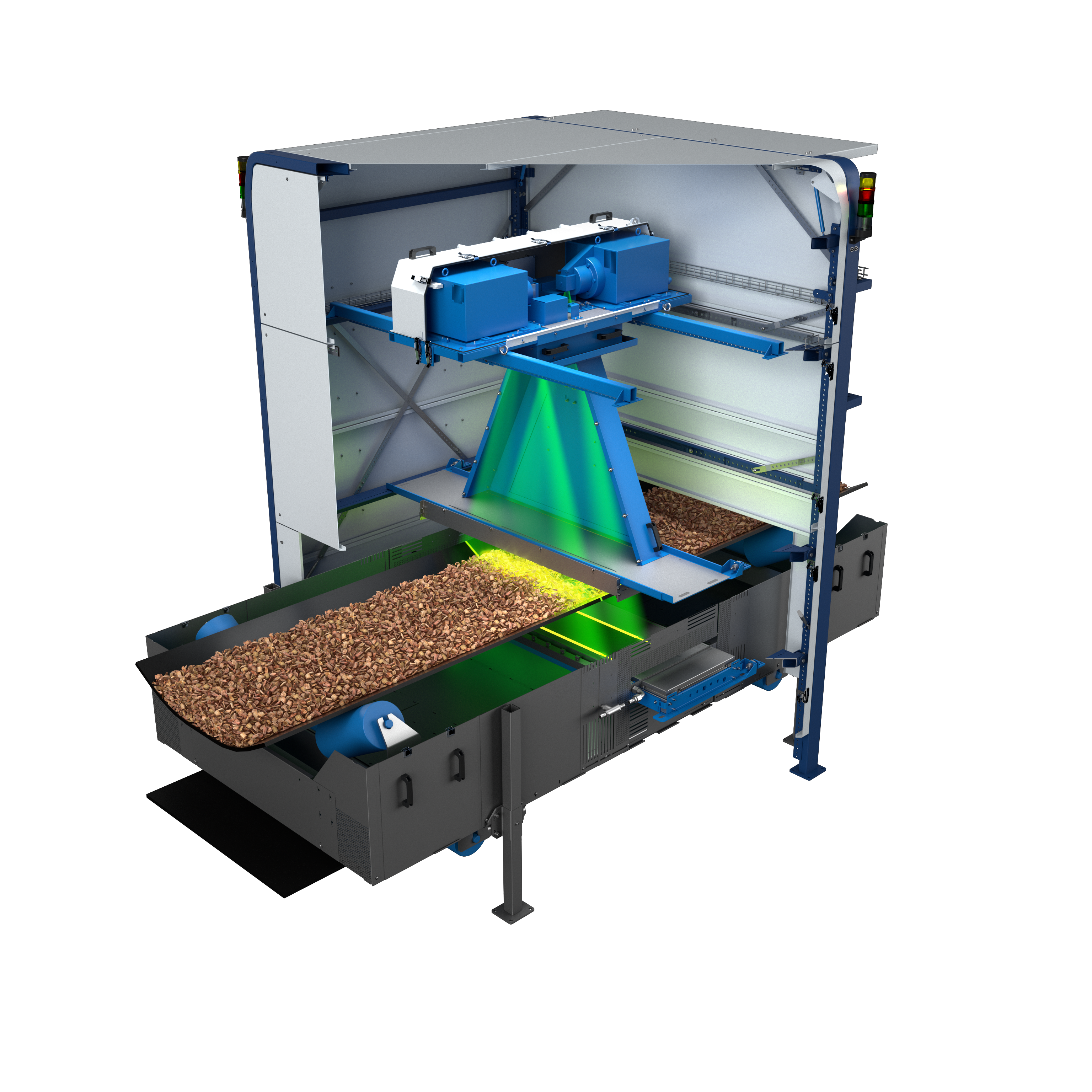

Precision woodchip dry mass flow and moisture improve the entire fiberline process

Increased material awareness

| Accurate cooking

|

Greater yields and increased cost efficiency

| Reduced cooking chemical consumption

|

Increase availability

| Increased process and production stability

|