The future of pet food extrusion starts here

Rising hygiene demands, and new nutrition trends call for smarter extrusion.

Meet ExMax S1021.

Designed to meet the highest food safety standards and easy maintenance requirements, it minimizes downtime and maximizes product consistency. Whether you're scaling up or optimizing performance, ExMax S1021 gives hygiene, efficiency, flexibility and reliability to the core of your operations.

The extruder which drives efficiency to deliver growth that matters

Peace of mind with guaranteed safe operations

The DensiFlex® system ensures safe pressure release and automatic control of starch cooking and expansion.

This means consistent product quality, fewer manual steps, and safer, smoother operations.

Flexibility for every batch

Seamlessly switch between recipes, textures, and nutritional profiles with minimal adjustment time keeps you

agile in a fast-changing market.

Efficiency that pays off

With automatic lubrication, IE4 direct-drive motors, and smart energy monitoring, ExMax cuts waste, lowers costs,

and delivers reliable performance day after day.

Elevated food safety standards

Built to meet EHEDG hygiene standards, ExMax features easy-to-clean surfaces, food-grade materials,

and automated cleaning reduces downtime while keeping safety front and center.

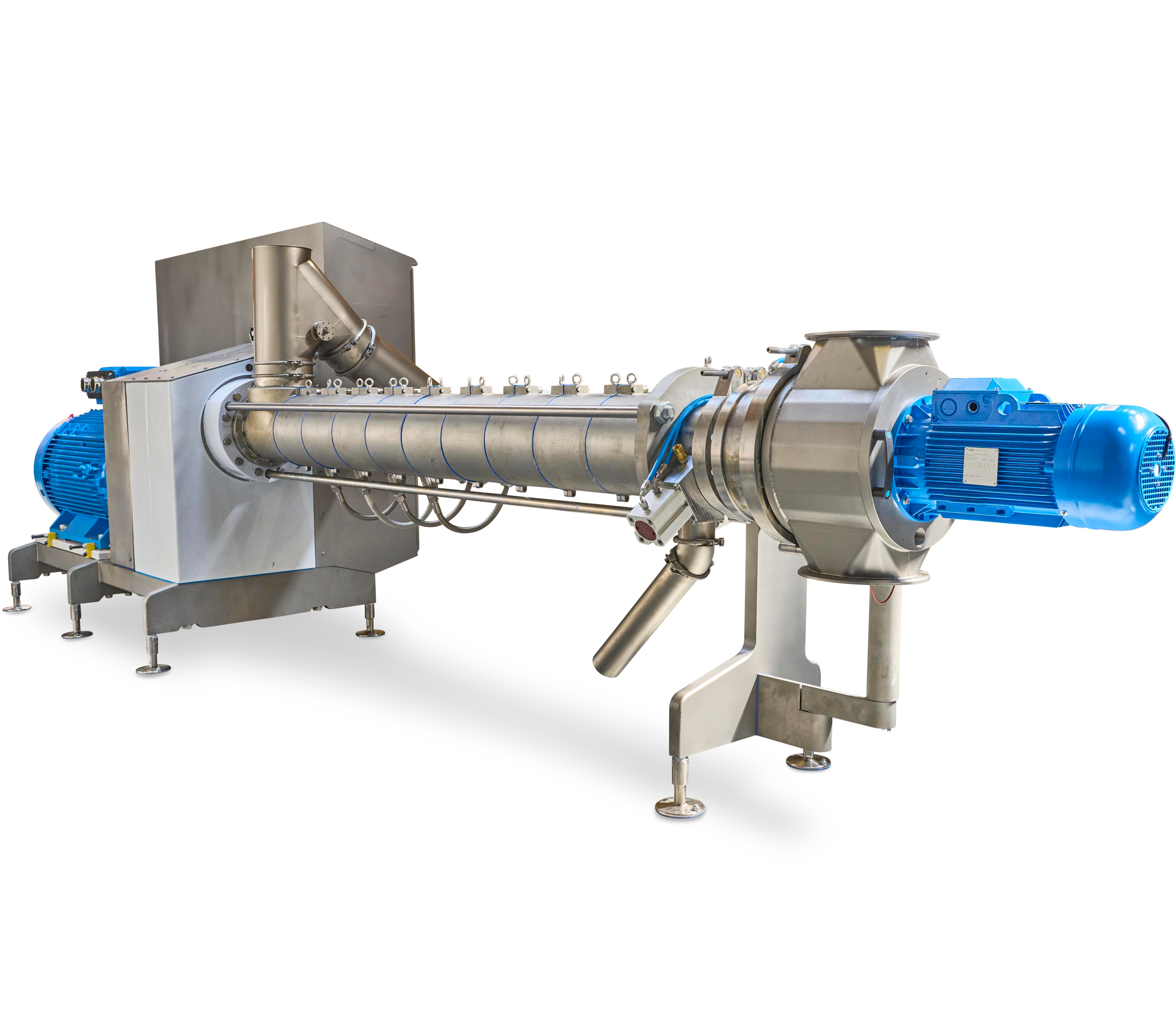

ANDRITZ ExMax s1021 Extruder

Key features that deliver

Hygienic design

EHEDG-compliant design, food-grade materials, and an automated cleaning system ensure effective and fast cleaning and uncompromised food safety.

Patented DensiFlex® System

Ensures safe pressure release, accurate starch control, and smooth transitions between recipes with minimal operator input.

Automation

Automatic lubrication, liquid dosing, and real-time monitoring of steam and energy optimize performance and reduce manual work.

High-efficiency drive

IE4 direct-drive motors and optimized gear transmission deliver high efficiency, low energy loss, and stable performance.