Integrating all existing process areas with technology specifically for dissolving pulp production.

Drying dissolving pulps

ANDRITZ is well equipped to supply turnkey market dissolving pulp drying plants.

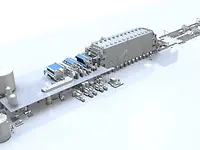

A market dissolving pulp sheet drying plant usually starts at the high density storage tower directly after the bleaching plant of the fiberline and includes pulp screening/cleaning, dewatering, drying, baling and bale finishing and/or roll finishing.

ANDRITZ is well equipped to supply leading technologies for turnkey market dissolving pulp drying plants.

The main difference between the qualities of kraft pulp and dissolving pulp is in the content of alpha-cellulose, ash content, DCM-extractives, and the density of the pulp sheet.

Pulp screening/cleaning

Modern pulp sheet drying plants are equipped with a screening/cleaning system in order to achieve the highest pulp cleanliness.

Pulp dewatering

Perfect sheet formation and the highest wet sheet tensile strength are important factors in the availability and successful operation of a large single pulp drying line. ANDRITZ offers three different types of pulp dewatering machines:

- Twin Wire Former

- Twin Wire Press

- Fourdrinier machine

Pulp drying line for dissolving pulp

ANDRITZ Twin Wire technology is the leading technology for pulp sheet drying plants today.

Pulp sheet drying

Based on Fläkt technology, ANDRITZ has continuously improved the pulp sheet drying technology. The ANDRITZ pulp sheet dryer is known worldwide for its excellent performance (market share exceeding 90%) and provides the following features:

- Over 480 references

- Optimized blowbox design for high heat transfer to sheet

- Low steam and electrical power consumption

- Increased floating height and strong sheet fixation

- Improved cleaning tools (blowbox lifting, broke removal nip) for faster cleaning

- Automatic tail threading system for fast threading at full machine speed

Pulp baling – bale finishing

Pulp baling lines include reliable high-speed cutting, bale handling, and wrapping of dried market dissolving pulp:

- Cutter/layboy

- Baling line (e.g. conveyor system, bale scale, bale press, duowrap, end folder, stenciler, bar code printer, stacker)

- Tying equipment (e.g. bale binder, unit binder)

- BaleMatic pulp baling and finishing control system

ANDRITZ has successfully further developed state-of-the-art pulp baling technologies by revising the design and technical features to provide customers with sophisticated and reliable systems.

Pulp roll finishing

For specific market dissolving pulp grades, a roll finishing system may be used in addition to or instead of a pulp bale finishing system.

Automation

ANDRITZ has its own automation department supplying the systems for monitoring and controlling a complete drying line.

Upgrades, rebuilds and services

ANDRITZ has completed numerous successful projects for upgrades, rebuilds, and conversions. We assist in the early stages of a project by performing plant surveys, upgrade studies, and pilot plant trials.