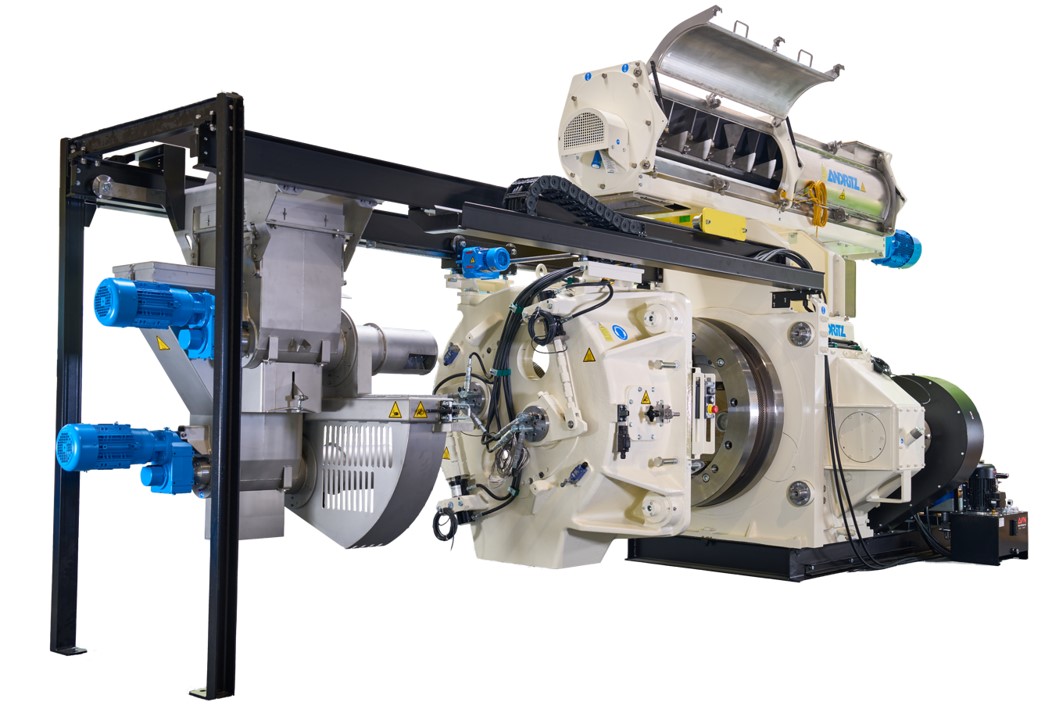

The PM30-6 Pellet Mill

Decades of proven performance – Now even better

The PM30 pellet mill has long set the benchmark for excellence in biomass pelleting.

The new PM30-6 continues this legacy with higher reliability, longer lifetime of wear parts, and lower operating costs.

Designed specifically for biomass, wood residues, agricultural residues, and energy crops, it is now available for both new installations and retrofit upgrades for PM30-4 and PM30-5 models.

Key technical improvements

- Optimized die speed increases capacity while reducing specific energy consumption

Patented Feeding System ensures even material distribution and reduced mechanical stress

Oil lubrication system enables grease-free operation with improved cooling and extended bearing life

Hydraulic roller system allows rollers to engage and retract during operation for faster cleaning and easier start-up

Proven Results

The new PM30-6 sets a higher standard in pelletizing efficiency. Compared to earlier PM30-4 and PM30-5 models, it delivers measurable gains in throughput, energy efficiency, and reliability.

Key metrics:

- Up to 10% higher capacity with no increase in energy consumption

- 98% uptime maximizes TCO & OEE

- Extended die and roller lifetime

- Enhanced safety and serviceability

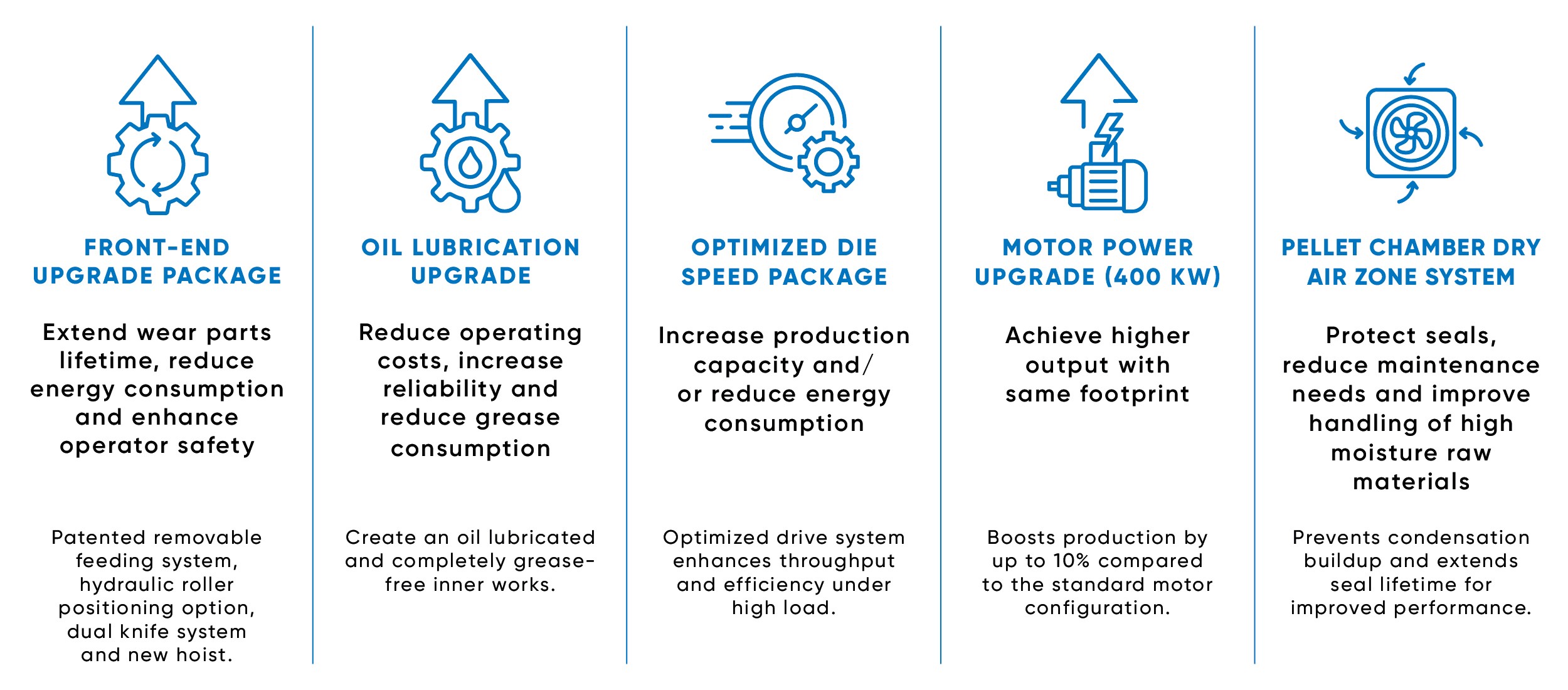

Retrofit upgrade options

Upgrade your existing PM30s to PM 30-6 standards.

Modernize your existing equipment with PM30 Retrofit Upgrade Packages.

These upgrades integrate the latest PM30-6 technologies into your current pellet mill, maximizing performance and minimizing investment.