Open contact form and submit your message

Products

As a leading supplier of electromechanical equipment, we provide comprehensive automation systems. Our hydropower automation offerings include hardware and software products, installation, commissioning, and operator training tailored to each power plant's operational strategy.

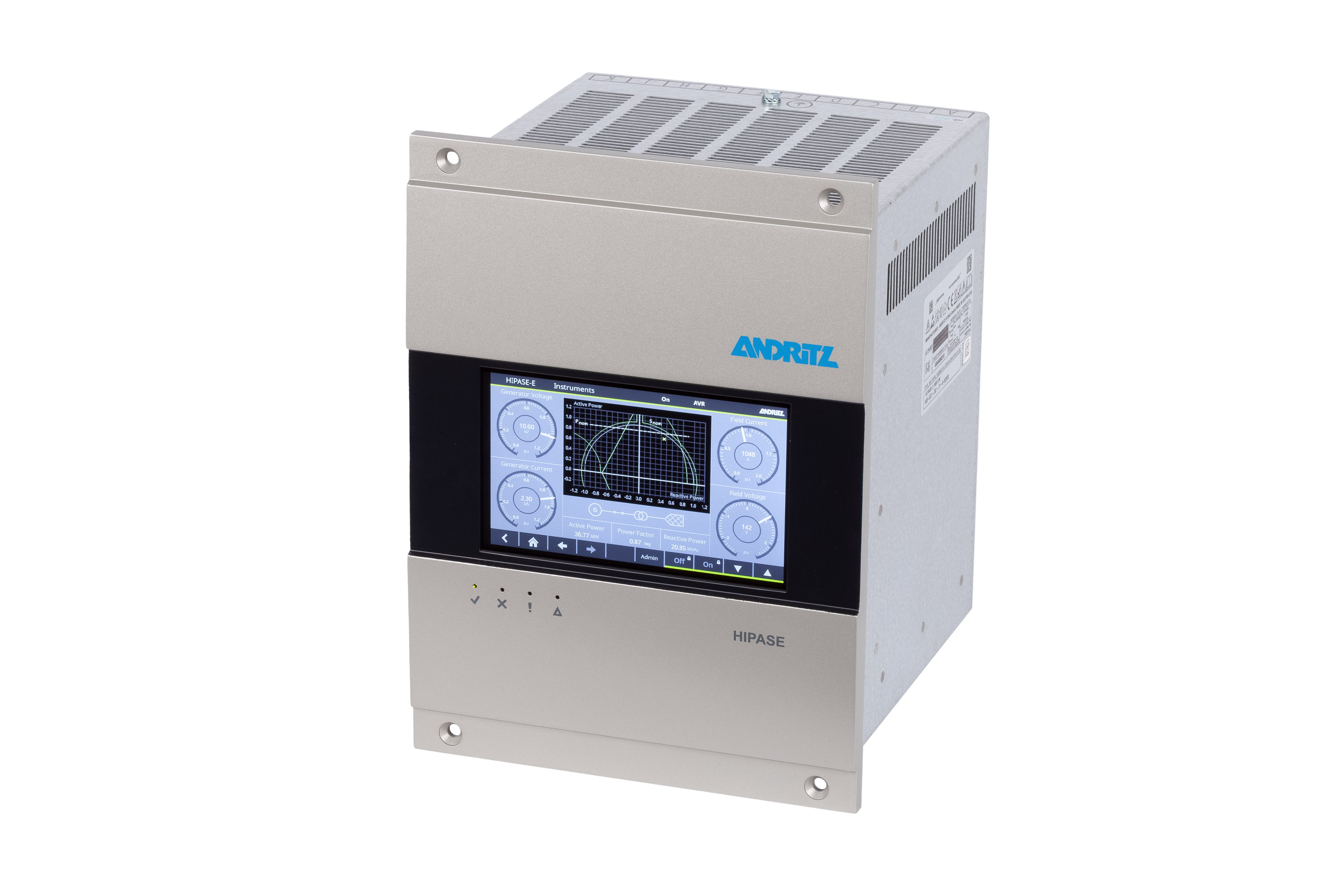

HIPASE Device

Integration on highest level

ANDRITZ Hydropower has extensive and long-term experience in the fields of excitation, electrical protection, synchronization, turbine governors and automation of hydropower plants, forming the basis for the development of the new HIPASE product platform. As a worlds first, HIPASE does integrate all the specific requirements of the different applications in a single device based on a highly performing and perfectly adapted platform.

The new and innovative HIPASE platform has especially been developed for the use in hydropower plants and covers the following applications:

- Excitation (HIPASE-E)

- Protection (HIPASE-P)

- Synchronization (HIPASE-S)

- Turbine Governor (HIPASE-T)

All devices are running on the same hardware, the same device firmware and can be programmed with the same engineering tool. This is absolutely unique and offers great benefits for spare part handling, usability and training.

Due to the scalability and the high performance of the platform, it is also possible to combine two applications onto one physical device. The following combinations are available:

Protection and Synchronization: HIPASE-PS

Excitation and Turbine Governor: HIPASE-ET

This once again has great benefits especially when thinking about cubicle space during rehabilitation work, cost effectiveness and overall system performance.

Hardware

All HIPASE devices are built according to a modular system specifically for your needs.

The hardware of HIPASE devices be combined individually according to the field of application. Depending on the amount of I/Os (Digital, analogue as well as CT and VT inputs) a half or a full 19” housing is used. The hardware boards and their functionality can be used across all HIPASE applications.

The central Processor Board is the core component, also supporting the following standard communication interfaces:

- IEC 61850 (MMS and GOOSE)

- IEC 60870-5-103

- IEC 60870-5-104

- Modbus TCP

- OPC UA

- FTP

All HIPASE devices feature a 7” full-graphic color touch panel which can either be mounted directly on the device or as an external display in the cubicle door.

Engineering

The HIPASE Engineering Tool offers a very easy, fast and reliable way to engineering, program and maintain HIPASE devices. It was developed with the same idea as the HIPASE hardware – to offer a new and unique approach for Hydro power automation. The same HIPASE Engineering Tool can be used to engineer all HIPASE applications (standalone and combined). This once again offers great benefits for all phases of the lifetime of the HIPASE devices.

All parts are taken care of with the same Engineering Tool:

- Hardware assembly

- Defining protective functions, parameters for regulators or the synchronization function

- Programming Function Block Diagram according to IEC 61131

- Adding or changing information on the integrated full color touch panel

- Diagnostics, Documentation and maintenance

The engineering workflow is supported by the integrated, intuitive and context sensitive help functionality.

Security

Cybersecurity is at the core of the HIPASE platform. It is one of the key elements starting from the early concept stage up to the current R&D roadmap.

Separating the core application and the connection to the outside world (Communication protocols) onto two physical CPUs is the most significant sign that Cybersecurity sits in the heart of HIPASE. This ensures, that changes on the Communication CPU do not have any influence on the Application CPU.

Additional software measures like Firewalls, encrypted communication (between HIPASE Engineering Tool and the HIPASE devices as well as connections via encrypted standard protocols) and regular cyber security updates ensure, that HIPASE does withstand cyber attacks. HIPASE also complies with the industry standard of “System hardening” – a way to ensure only necessary ports and functions are active in the system.

HIPASE-250

Control Center System

The SCADA system HIPASE-250 provides all functions for operating, monitoring and controlling the entire technological process. Thanks to its scalability, it can be used at all levels of automation, from turbine controllers up to large central control rooms.

HIPASE-250 offers a wide range of configuration options. Starting with touch devices, singular and redundant PC systems, through to dedicated distributed server systems. The support of remote desktop enables the use of thin clients and mobile devices. Hot standby redundancies and geo-redundancy increase the availability of the system. Availability can be further increased with additional emergency systems and test systems. Consistent support of virtualization systems offers you flexibility in the hardware configuration.

The user interface has been carefully developed in accordance with the state of the art in industrial design. The focus and reduction of the visualization to the essentials results in an optimal user experience. The design of the user interface is based on the recommendations of the “High Performance HMI” and the standards in accordance with “IEC 63303 - Human-Machine Interfaces for Process Automation Systems”, “IEC 62682 - Management of alarms systems for the process industries” and “ISA 101 - Human-Machine Interfaces”. Specialized displays tailored to hydropower optimally support the operating staff by visualizing generator diagrams, turbine flow diagrams, turbine CAM diagrams and dashboard views.

HIPASE-250 is a multi-hierarchical SCADA system that can be used at all levels of the hydropower process thanks to its excellent scalability. The engineering tool of the HIPASE platform enables fast, ergonomic and thus efficient engineering. Due to centralized engineering, each system can be loaded with new or modified data without interruption. Productive operation is not restricted in any phase of the engineering workflow. Thanks to version decoupling, the SCADA systems used can be operated in any software version.

With its cross-platform capability, HIPASE-250 can be operated with Windows and Red Hat Enterprise Linux operating systems. From a cyber security perspective, this operating system diversification raises product security to a new level. TLS encryption for all communication protocols, system hardening according to CIS Level 2, a secure kiosk mode, role based access control (RBAC), Single Sign-on (SSO), two-factor authentication (2FA) with smartcards are elements that significantly increase operational security.