Servo driven roll feeder from 100mm to 1600mm strip width

Standard roll feeder or optional high speed roll feeder for advanced applications

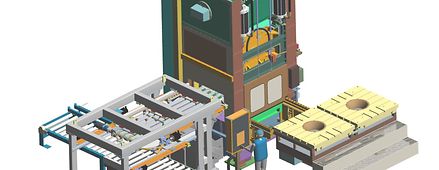

However, a forming line consists not only of the press but of a number of ancillary equipment and auxiliary units, which only result in a functioning system as a whole. We have more than 70 years experience in the integration of press and peripherals. Our experts know exactly the mutual dependencies and requirements of the individual sub-systems.

Profitability and productivity are the result of an optimally coordinated system. We are happy to advise you on the planning of your forming plant.

Standard roll feeder or optional high speed roll feeder for advanced applications

Optionally with linear direct drives or standard servo motors

Brackets, clamps, movable table plate, single or tandem-tool-changing-shuttle, moving bolsters

Optionally in short or long form

From standard roller up to high tech spay cabin

Pneumatically or hydraulically driven cutting shear units, alternatively mechanically driven units

Pneumatically or hydraulically operated

From single conveyor to complete automatic scrap transport systems

From standard conveyor to complete automatic stacking unit on wood pallets or trays

Progressive or transfer tools