Evolution not revolution

Tissue machine creping

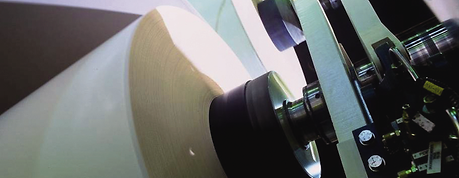

ANDRITZ tissue machines provide solutions for all requirements in tissue production. The creping position is one of the key factors in the final appearance and performance of the tissue product and is an area that ANDRITZ considers critical within the process.

Creping

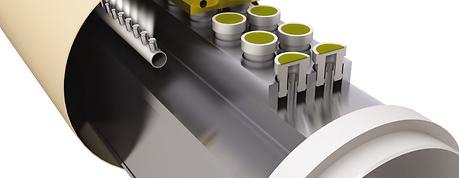

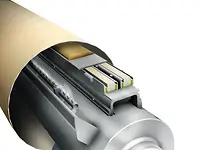

The crepe blade is the point at which the final sheet appearance is created. The geometry of the blade and its application are critical in establishing the best possible end product. Specifically designed for tissue applications, the crepe blade, along with the Yankee against which it operates, is the heart of the process.

The doctor holder uses a special pneumatic loading arrangement to load the blade against the Yankee cylinder and has a “flexible finger” type backing. The mechanical lock prevents collision of the holder with the cylinder when there is no blade in place. For certain applications and upon request, a stiff holder can be substituted.

Angle adjustment

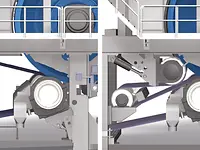

The doctor assembly is adjustable for different applications and end product properties. The entire assembly can be rotated on the assembly journal by means of a jacking bolt that changes the position of the assembly relative to the loading cylinder stroke.

At a glance

- Flexible holder ensures even application of the creping load.

- Adjustable angular position allows flexibility for different products and properties.