Solutions

We provide comprehensive solutions for secondary hydropower plant equipment. All over the world, more than 500 employees have created an extensive knowledge base for secondary equipment within all types of hydropower plants. Decades-long experience of automation, protection, excitation, turbine control, and power plant regulation is combined to deliver optimal solutions.

Excitation systems

The Excitation system of the synchronous machines either used as generator, motor or condenser are the backbone for production of the reactive power, needed to integrate renewable energy sources into the public grid.

The Excitation System provides the following services:

Supply of a controlled direct current for the rotor

Control of the voltage and reactive power output of the synchronous machine.

Damping of power oscillations in the electrical grid.

Stabilizing of generators during grid failures, to minimize the forced outage in the grid.

Keep the synchronous machines within the operational limits.

HIPASE-E

HIPASE-E is an automatic voltage regulator (AVR) and sequencer for the control of a modern thyristor based excitation system. This system could be used for the control of all case of synchronous machines, independent if they are used as generator, motor or synchronous condenser.

The software structure is compliant to the IEEE Standard 421.5 Models and includes all required limiter functions, as well as the Power System Stabilizer (PSS) of the type PSS2 or PSS4.

The parametrization and programming of the controller is done graphically by means of function block diagrams, with a state-of-the-art Engineering tool.

The design of graphical user interfaces (HMI) for operation and supervising of the excitation is also directly included into the tool, so that only one dedicated tool is required.

The HIPASE devices are designed to allow a simple integration into remote control environments by several communication protocols. The devices can be used either in single or fully redundant configurations, so that a high availability could be guaranteed. The software and communication interfaces are designed to fulfill the highest cyber security standards, to avoid harm from cyber attacks.

ANDRITZ Hydropower provides four types of THYNE excitation systems:

THYNE1, Compact Excitation device with IGBT technology up to 25 ADC, typically used for brushless or DC exciters.

THYNE 400, modular thyristor based system up to 400ADC, for brushless or DC exciters.

THYNE 500, modular static excitation system up to 2000 ADC

THYNE 600, modular static excitation system up to 8000 ADC

The THYNE system stands for:

Comprehensive technology and know-how

Extensive long-term experience in all type of excitation systems

Flexible solutions adapted to the need of the customers

High availability and efficiency

Robustness and high MTBF times

Lifetimes and support for 20 years and more

Long time spare part availability

Training center for Engineers

Our engineers are supporting the customer with cost effective solutions, which includes smart upgrades, so that existing system components could be used until the end of their real lifetime. One example is to exchange only an obsolete AVR and reuse the existing power electronic with a new Controller for the next decades. Such concepts allow to minimize outage times and the cost of such investments.

In order to fulfill the obligations for the grid connection, we are supporting our customers with simulation models, parameter and verification studies for the excitation system. We have a dedicated team of specialists who have the required experience to do such task for multiple countries.

Protection systems

Electrical protection systems have to take on the task of damage containment in the event of overloading and/or a fault in the electrical equipment (generators, transformers, auxiliary systems, busbars, outgoing lead and cable units).

Power plants, transmission systems (grids and grid components) and electrical consumers have varying equipment items with different levels of priority. Many years of operating experience form the basis for sizing and choice of equipment, and also define the respective protection “philosophy” in each case.

In modernization of protection systems in existing plants, versatile and flexible equipment and systems should provide optimum solutions, both technically and economically.

HIPASE-P

HIPASE-P is a perfect solution for powerful generator and transformer protection designed for different frequencies (50 Hz, 60 Hz and 16.7 Hz).

The structure of the protection functions is modular and may be customized. Based on the long-term experience with the DRS protection device family of ANDRITZ Hydropower the proven numeric algorithms are used and modified to the new requirements in the power generation.

For HIPASE-P a special application board has been developed to generate or process analogue signals for specific protection functions.

Examples for these protection functions are:

- Rotor earth fault protection

- Stator earth fault protection by

- signal injection method

- Shaft current protection

- SFC protection

- Temperature measurement, etc.

Using the compact housing (half size 19”), up to 32 digital inputs and 36 outputs may be processed. For more comprehensive applications with a larger amount of digital input and output signals, a full size 19” housing is used. Generator protection requires numerous functions which are needed for advanced applications like pump turbines or even large thermal blocks.

The HIPASE Engineering Tool supports the protection engineer with proven tools such as software trip matrix, test inputs for the protection functions or simple interface testing.

The engineering of protective functions can be done with the help of a simple selection of all available HIPASE-P functions.

With this action all required steps for the engineering will be fully automatically generated. This includes even the creation of process displays.

In addition, a parameter window for a simple parameter setting is available.

Turbine governor

The turbine governor consisting of the hydraulic power unit (HPU) and the digital governor is the system which controls the hydro turbine in respect to speed and power.

The operation of the turbine governor must be guaranteed under all conditions, even with difficult ambient conditions. efficient remote functions are needed for fast and easy maintenance and service access.

The availability of the speed sensors, , and the accurate positioning of the servo-motor guarantee reliable operation and control of speed and power. In order to guarantee easy maintenance, the mechanical design features modular structure and reliable components. The design of the hydraulic power unit and the digital governor is based on international standards.

HIPASE-T

The turbine governor controls the forces when theunit converts the existing hydraulic energy into electrical energy in the most efficient way. It ensures stable speed of the turbine in no-load-operation as well as island-mode and guarantees the adherence of setpoint in grid operation.

The control algorithm considers the increased challenges for the digital turbine controller with regarding frequency and primary controlwhich are required by the ancillary services for the grid. The requirements of the different turbine types (Francis, Kaplan or Pelton) and sizes of the units are supported by a modular application concept.

In order to secure an easy interface to project specific requirements, the application board for turbine control contains all relevant types of in- and output signals.

Thus dedicated interfaces for speed sensors as well as generator voltage measurements for the speed measurement are foreseen. In addition, analog in- and outputs for the measurement of positions and CT/VT interfaces are available.

The analog outputs can be configured as voltage or current outputs with variable limits.

Hydraulic power unit (HPU)

ANDRITZ Hydropower offers complete oil hydraulic power unit (HPU) packages including sump tank, pumps, control and main relay valves, filters, monitoring devices, and pressure accumulators. The standard concept has a modular design with use of reliable industrial components and design pressure up to 250 bar.

Preferably we use selfSelf-regulating axial piston pumps for the main oil supply are preferred, but constant pumps (e.g. screw or gear type) with special pump control blocks can also be used.

Special hydraulic features needed for the turbine control - like pump control blocks, failsafe function on main relay valves, special shape of control edges on main relay valves, etc. - have been developed in order to guarantee maximum reliability and safety.

A series of standard, but tailor-made main relay valves are available for special applications on old low-pressure systems as well as on new turbines requiring high operating capacity.

The hydraulic system is designed together with the actuating elements, both for new plants and rehabilitation projects.

Digital turbine governor

ANDRITZ Hydropower turbine governors stand for flexible and reliable turbine control. The new challenges on grid stability are faced by means of the load frequency algorithm.

The digital turbine governor gets by with the functional requirements of the client because of a scalable and modular solution. It can be implemented as stand-alone solution or as integrated part of the existing structure. Preceding simulations and stability studies ensure stable and reliable control.

The governor performs different tasks during operation. Beginning with the start of the turbine on demand and stabilizing the speed for synchronization, it ensures stable load control when the unit is connected to the grid. Further tasks are supporting the grid frequency during primary control and fast reaction on load rejection and island detection. Due to the various requirements of the different operation modes, bump-less switching is vital for the turbine governor in order toto provide safe and preserving operation.

A variety of special functions are available related to the turbine type, e.g.

Flow calculation

Adaptive CAM optimization for Kaplan turbines

Surge control

Flush control for Kaplan turbines

Comprehensive operation with a high-resolution touch panel gives the operator the opportunity to interact with the turbine controller and to view all the status information on a central device. In addition, it allows local operation of the turbine within the defined limits.

Comprehensive services, spare part guarantees, and training classes complete our scope of delivery.

Synchronization systems

Safety and speed are not mutually exclusive when latest innovative technology is used.

The synchronization of rotating electrical machines and networks requires the highest quality and reliability and allows no errors. ANDRITZ relies on over 50 years of experience and a broad installed base in the field of synchronization for the development of its product portfolio. With the increasing demands on the availability and flexibility of electrical power supply, the synchronization process of rotating electrical machines and the power grid must also be fast and reliable, even under difficult conditions, to ensure the stability of electrical networks.

ANDRITZ offers HIPASE-S, an innovative synchronization system designed according to the highest demands of the energy market. The increasing complexity of synchronization applications requires not only a powerful device but also intelligent tools for operation and parameterization. The HIPASE Engineering Tool has been developed according to the latest principles of ergonomics and user-friendliness to handle every application quickly and safely.

HIPASE-S

HIPASE-S is a fast, highly accurate, and universal synchronization system for parallel connection of networks, lines (loaded/unloaded), generators, motors (pumps), and synchronous condensers, covering all application areas of power generation.

An integrated full-graphic touch panel shows all important status variables in a menu-guided manner and supports the test and commissioning phase by determining the optimal synchronization parameters in a time-saving manner.

In addition to extensive event logging, a high-resolution analysis tool with multi-stage automatic curve recording enables a detailed history of the last 100 synchronization processes. Built-in logging functions show process sequences and events, while high-resolution curve recordings enable quick and accurate diagnostics.

HIPASE-S is available in the following configurations:

2 circuit breakers, single-phase measurement for 50 Hz or 60 Hz

7 circuit breakers, single-phase measurement for 50 Hz or 60 Hz

2 circuit breakers, three-phase measurement for 50 Hz or 60 Hz

7 circuit breakers, three-phase measurement for 50 Hz or 60 Hz

7 circuit breakers for railway applications

In all configurations, an optimized frequency adjustment not only accelerates the synchronization process but also reduces the mechanical stress during switching to an absolute minimum.

Plant control

The SICAM product family performs local control tasks based on the principle that the time-critical process automation tasks in a multi-hierarchical network are performed as close as possible to the process.

With the help of this automation system, we can fulfill the following tasks and more:

- Turbine Governor

- Control of auxiliary functions

- Start/Stop sequences

- Monitoring and control of external services

- Communication to remote stations and control centers

Balanced functionality enables the flexible combination of automation, telecontrol and communication tasks. Supplemented by the scalable performance and various redundancy configurations, optimum adaptation to the respective process requirements can be achieved.

The use of IEC 60870-5-101/103/104 standards ensures seamless addressing from source to acceptor. But the use of various third-party protocols also enables seamless integration into existing automation networks, thus ensuring long-term security of previous investments.

HyNET & HySEC

HyNET forms the basis of secure communication inside and outside the power plant. Moreover, HyNET offers new and innovative solution processes.

The complexity of the fields of application, including the corresponding interfacing, inevitably results in a rapid increase in the danger of unwanted system access or malware contamination. Only a consistent security concept can align flexibility with the highest security requirements. A combination of security, availability and standardization is at the core of high-quality network engineering.

HyNET - the comprehensive, modular and custom-made network solution - has been designed to cater for these core topic areas.

Innovative solutions and a broad range of services can be achieved by a combination of experienced technical experts, defined processes and high-quality components. A comprehensive security concept is particularly important in network security.

Interlocking and interoperability of the security components lie at the heart of HyNET.

To meet such high system and network security requirements, the issue of security is considered comprehensively in HyNET and is put into practice as an integrated solution. The declared objective is a secure, scalable and manageable network which functions as a company-wide solution and also incorporates WLAN and VoIP.

Secure communication, efficiency and redundancy mean higher network and data security, lower operating costs, user satisfaction, and much more. HyNET combines a future-oriented environment and modern network technology for secure operation of power plants.

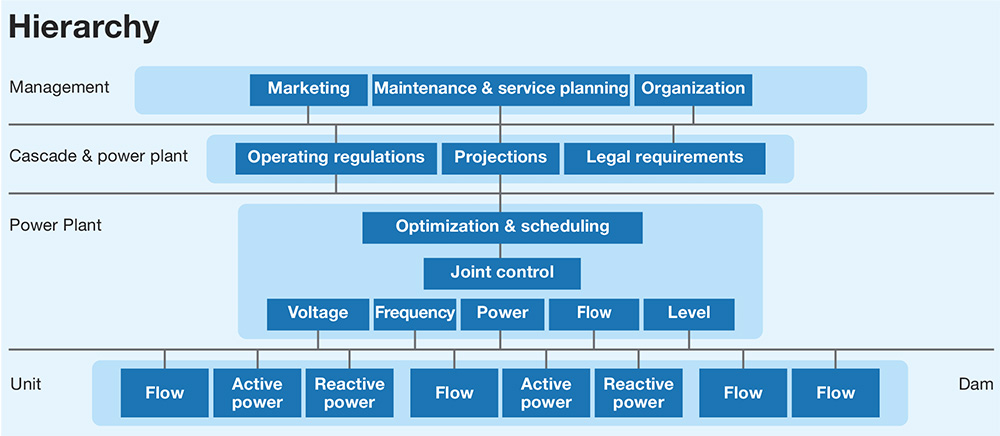

Power Plant Management

Power production must be maximized, while the costs should be reduced, both for single power plants as well as for power plant cascades. Modern power plant management systems perform these tasks very efficiently.

Beside the plant's operational requirements (e.g. maintenance cycle), the system has to take account of a number of external regulations, such as water management, contracts, and environmental regulations.

Due to the growing number of solar and wind power plants, optimum delivery of control energy (secondary control, tertiary control) is also gaining importance.

Production planning requires different modules for forecasting and optimization. Information has to be provided to other applications (e.g. commercial and administrative software tools) via standard interfaces.

All these different requirements require a modular overall concept.

Besides its main task - maximization of energy production - the system has to support the operators in various other operating conditions (e.g. normal operation, flood and disturbances). At the same time, the system has to contribute towards reducing operation and maintenance costs.

It must be possible to integrate the system easily into the power plant’s environment on the basis of the existing infrastructure.

Typical tasks of power plant management systems

Power plant control

- Head water level control

- Discharge control

- Power control

- Reactive power control

Authority and environmental regulations

- Downstream water flow limitation

- Filling and discharging gradients

- Level limitations

- Flood alert

Forecast

- Meteorological data (precipitation, temperature, snow depth, ...)

- Calculation of incoming water quantities

Optimization

- Energy production

- Reservoir utilization

- Swell operation of power plant cascades

- Production scheduling

- Secondary and tertiary control

Interfaces

- Equipment and maintenance database systems

- Commercial database systems

- Geographical information systems

- Office packages