Air removal benefits

Improved drainage and formation

Fewer pinholes and spots, less deposits

Increased production and machine efficiency

Improved consistency stability in stock entering the headbox

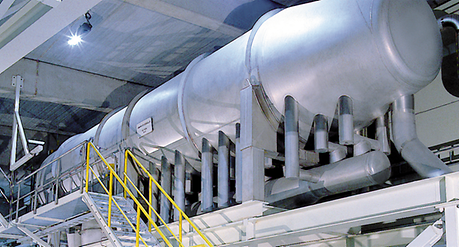

Complete deaeration of pulp ahead of modern, high-speed paper and board machines is a necessity. Pressure drops and micro-turbulence in the headbox release dissolved gas into entrained air bubbles. ANDRITZ’s experience with more than 900 deculator installations shows conclusively that complete removal of all free and bound air adhering to fibers yields the full benefits of deaeration. However, partial deaeration is sufficient in many applications, such as with several board machines. The ANDRITZ solution for partial deaeration is the ShortFlow deaeration device.

Multi-retention deculator MRD

FlyingWing deculator FWD

Improved drainage and formation

Fewer pinholes and spots, less deposits

Increased production and machine efficiency

Improved consistency stability in stock entering the headbox

Consistency disturbances are one of the causes of basis weight variations and are difficult to stabilize. ANDRITZ multi-retention deculators significantly reduce these disturbances. Stock flows through the feed manifold of the deculator, which divides consistency disturbances into smaller components as they pass through the SPINJET nozzles. Each small component has a different retention time inside the deculator. Due to the counter-direction of flow inside the deculator, random disturbances can be dampened or totally suppressed, depending on their frequency.

The flying wing deculator offers both complete deaeration and efficient cleaning of paper stock. The distribution of cleaner pipes on the deculator’s wings ensures thorough mixing of the stock and attenuation of any short-term consistency variations. The benefits of this design include:

ShortFlow deaeration offers partial deaeration where complete deaeration is not needed. Here the wire pit and vacuum air removal tank are combined into one unit, which replaces the conventional wire pit. Deaeration is based on air bubbles rising up due to gravity, which is improved with a vacuum. Short Flow deaeration has a flexible design and can be applied in practically all paper and board machines.