ANDRITZ Automation & Digitalization

Stabilizing, improving, and optimizing plant performance with ANDRITZ APC™

Remove bottlenecks, increase energy efficiency, produce higher quality products more consistently, and lower production costs.

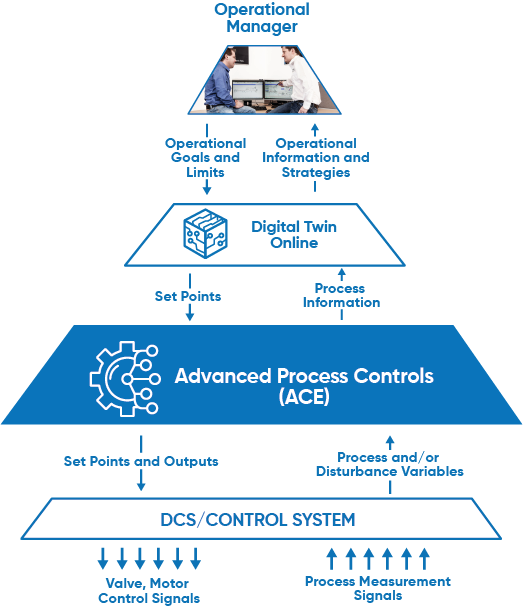

Advanced Process Control (APC) is an enhancement of the basic process control aimed at delivering value to our customers in terms of throughput, quality, and cost. APCs utilize various technologies to optimize the process in response to business drivers with minimum resources without compromising throughput, quality, and cost targets.

The APC supervisory process management system autonomously optimizes the process area based on cost/value. APC is an automated “expert operator” that works to fully optimize a process.

The expert operator in APC is always fully attentive, never distracted, and achieves optimum conditions for the plant. APC can be implemented to determine the best setpoints so that the process can operate at maximum efficiency.

ANDRITZ APC™ solutions for Paper mills

ANDRITZ offers a suite of Advanced Process Control solutions to enhance industrial operations

Control optimization with ANDRITZ APC (Advanced Process Control). “It works reliably – better than our best operator” is how APC multivariable, predictive, and adaptive controller is described by many mills.

The APC supervisory process management system autonomously optimizes the process area based on cost/value. APC is an automated “expert operator” that works to fully optimize a process.

Key characteristics:

- ANDRITZ Knowhow built into Advanced Plant Control Advanced Process Control Libraries

- Efficient and consistent deployment of controls

- Embedded documentation of control functions

- Available for final Customers’ deployment via a low-code