ANDRITZ HYDRO GmbH

Turbo generators for thermal power plants

ANDRITZ Hydro is a global supplier of turbo generators with output ratings from 10 MVA to 350 MVA.

The turbo generator center of competence of ANDRITZ Hydro is organized in a separate division and located in Austria.

The historical brand "ELIN" has been integrated into the ANDRITZ Hydro business area, providing decades of experience and comprehensive know-how. In order to secure high quality and short delivery times, ANDRITZ Hydro has its own welding and machining facilities for the turbo generator business.

The product range covers three different areas

- 10-56 MVA: four-pole design, air-cooled

- 50-220 MVA: two-pole design, air-cooled

- 220-350 MVA: two-pole design, hydrogen-cooled

Four-pole air-cooled turbo generators

- Range from 10 MVA to 56 MVA

- More than 150 four-pole turbo generators have been supplied

Features

- cylindrical laminated rotor design or salient pole rotor design

- standardized frame sizes

- end shield design

- GVPI (global vacuum pressure impregnation) or VPI (vacuum pressure impregnation) technology

- stator coil-winding or bar-winding design

- brushless or static excitation

- air/water coolers, air/air coolers or open ventilated configuration

- low noise and vibration levels

- packaged design to enable short installation cycles

- excitation and protection system, LS/NS cubicles, bus ducts, synchronization

Reference highlights

- 1977: first 4-pole turbo generator, 1.25 MVA, 6.6 kV, 1,500 rpm

- 1993: 36 MVA, 4-pole turbo generator, 6.3 kV, 1,500 rpm

- 1996: 50 MVA, 4-pole turbo generator, 10.5 kV, 1,500 rpm

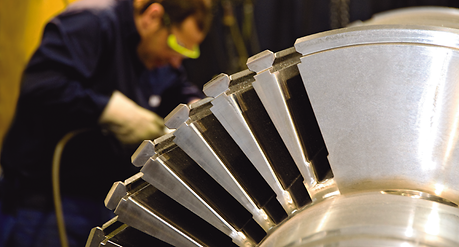

Manufacturing of a turbo generator

Two-pole air-cooled turbo generators

- Air-cooled turbo generators from 50 MVA to 220 MVA

- Hydrogen-cooled turbo generators for ratings up to 350 MVA

- More than 850 air-cooled turbo generators have been supplied

- Features:

- up to 220 MVA, capable of synchronous condenser operation

- VPI technology (vacuum pressure impregnation)

- brushless or static excitation

- air/water coolers or open-ventilated configuration

- low noise and vibration levels

- packaged design to enable short installation cycles

- excitation and protection system, LS/NS cubicles, bus ducts, synchronization

Reference highlights:

- 1970: First hydrogen-cooled turbo generator, 180 MVA, 10.5 kV, 3,000 rpm

- 1972: 330 MVA hydrogen-cooled turbo generator, 21 kV, 3,000 rpm

- 1973: 850 MVA, hydrogen-cooled turbo generator, 21 kV, 3,000 rpm

- 1981: 470 MVA, hydrogen-cooled turbo generator, 21 kV, 3,000 rpm

- 1991: first turbo generator supplied to GE, 45 MVA, 11.5 kV, 3,000 rpm

- 1993: 160 MVA, air-cooled turbo generator, 15.75 kV, 3,000 rpm

- 2002: 175 MVA, air-cooled turbo generator, 15 kV, 3,000 rpm

- 2008: 220 MVA, air-cooled turbo generator, 15.75 kV, 3,000 rpm

Two-pole hydrogen-cooled turbo generators

- Hydrogen-cooled turbo generators for ratings up to 350 MVA

- More than 20 hydrogen turbo generators have been supplied

Since 1991, ANDRITZ Hydro has cooperated closely with the global market leader for gas turbine power plants and thermal power plants with regard to two-pole, air-cooled generators and has established itself as the co-development partner in this area. From the beginning of the cooperation until the end of 2010, customers were supplied with 722 two-pole units, with a total output of 83,000 MVA. The overall experience of ANDRITZ Hydro in this business field covers 991 turbo generators with an output of 94,500 MVA.