Service for L-M-EVO-series refiner and feeding equipment

ANDRITZ plug screw feeder service

Our knowledge of the processes and equipment, and state-of-the-art refurbishment methods allow us to offer a wide range of product developments to help pulp, paper, panelboard and bioenergy companies remain competitive by extending the service life of the equipment.

ANDRITZ is a leading supplier of new equipment – and also the leader in providing improvements, upgrades, and services to increase the service life and performance of installed equipment. ANDRITZ offers rebuilds, spare and wear parts, upgrades, and on-site services for equipment from any OEM.

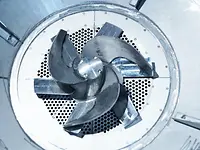

Plug screw feeder services

- Plug screw feeder refurbishing: state-of-the-art methods to ensure the best geometry, quality, and easy start-up of plug screw feeders, MSD Impressafiner, and chip press components

- Plug screw feeder protection: application of process-optimized hard facing materials to extend the service life of components

Plug screw feeder upgrades

- Compression housing with bolted anti-rotation bars and replaceable wearparts: reduces downtime and improves performance (dewatering efficiency, reduced fiber loss, liquor uptake, etc.)

- Split compression housing: for easier and shorter maintenance times

- Tailormade 3D plug screw geometry: determines and adapts exactly to operating characteristics (throughput, compression rates, and dewatering performance). The plant run-up process is shortened and downtimes are reduced.

- Advanced drainage compression housing

- Single-flight/double-flight plug screw feeder geometry: improves operating characteristics (throughput and dewatering performance) and component lifetime

Plug screw feeder spare and wear parts

ANDRITZ offers parts for plug screw feeder and MSD Impressafiner for any OEM equipment (e.g. screw, compression housing, spool, etc.). When required, parts and professional on-site support are available at short notice.