Real Time

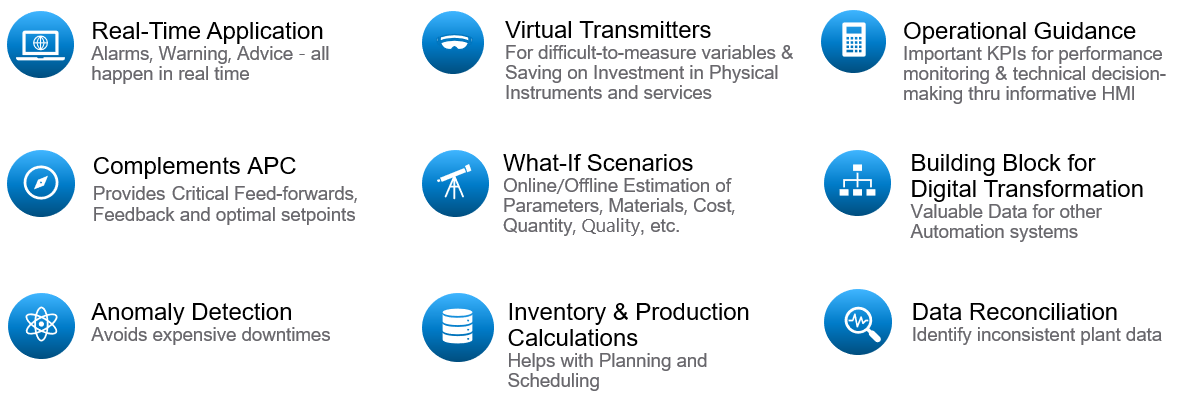

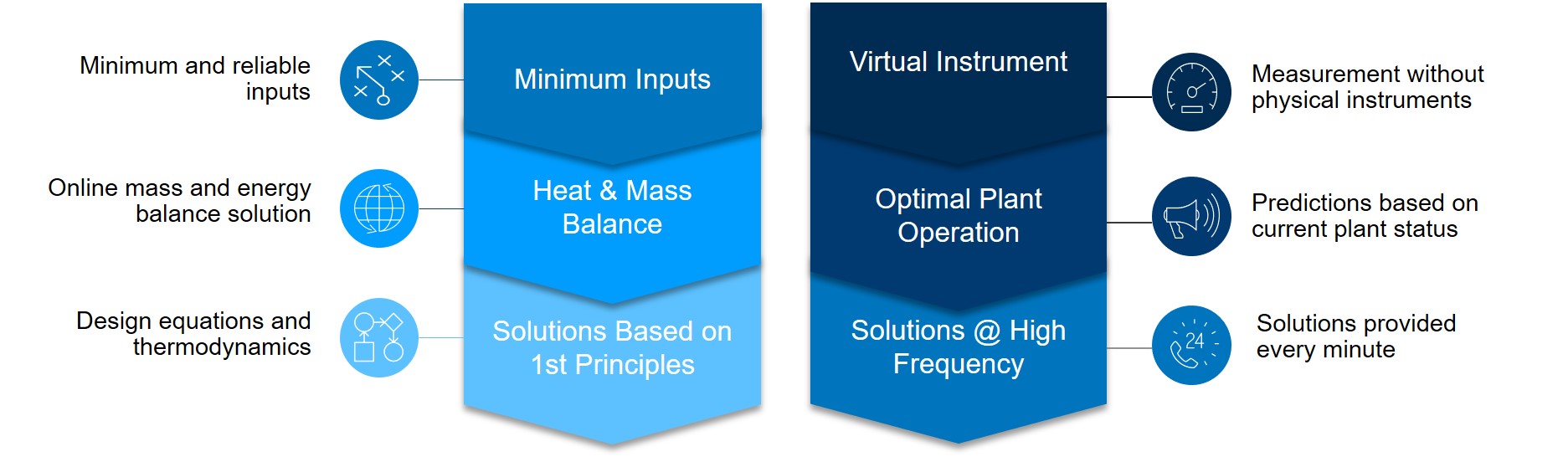

The Metris Digital Twin shares data in real-time with the operating plant. Inputs to the Digital Twin may be from field instruments, lab data, operator entry, and others, and at whatever available frequency. The Digital Twin captures the current plant status, including disturbances in measured values, and sends its resulting data back to the plant through the control system – all in real-time.