The brain behind your operation: Metris addIQ control systems

ANDRITZ Aqua-Screen coarse and fine screens for efficient solid separation in wastewater treatment plants

ANDRITZ Aqua-Screen solutions deliver advanced screening technology for municipal and industrial wastewater treatment plants. Engineered in stainless steel and optimized for solids removal, they protect downstream equipment, boost screening efficiency, and cut maintenance through automated cleaning and modular, front access service ability.

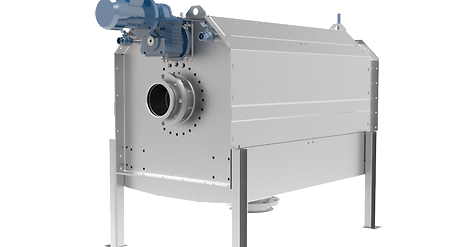

ANDRITZ Aqua-Screen fine screen, specially designed for handling municipal or industrial wastewater streams

What are Aqua-Screen fine screens and how do they work?

Fine screens at the headworks remove suspended solids early, stabilizing flows, safeguarding equipment, and improving overall plant efficiency. Selection depends on flow, load, and the size/character of screenings, ensuring the right aperture size, screening capacity, and hydraulic loading rate for each site.

Role in headworks and filtration

By capturing debris before biological or tertiary stages, Aqua-Screen systems reduce clogging, lower sludge handling demands, and limit wear on pumps and aeration equipment.

Aqua-Screen T and P fine screen, a modular concept for greater flexibility and cost savings

With its modular concept and common frame (less than 30 minutes for complete replacement of filter element), reducing maintenance time and number of different spare parts, the ANDRITZ Aqua-Screen fine screen is a high-tech solution adapted to your needs, integrating all existing screening categories:

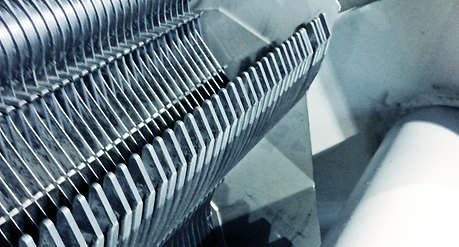

- ANDRITZ Aqua-Screen T – Toothing system allows effective, two dimensional fine screening and a lifting capacity (dimensions/quantity) unrivalled on the market; can be adapted to any application (formerly known as Aqua-Guard). It also features an automatic detection of wear on supporting rail (on XL T version only)

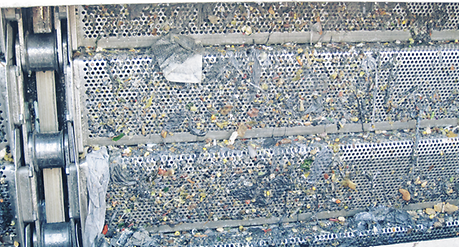

- ANDRITZ Aqua-Screen P – Perforated plates system allows circular, two dimensional fine screening – one of the most efficient on the market; can be adapted to most applications

ANDRITZ Aqua-Screen T fine screen – Toothing system

ANDRITZ Aqua-Screen P fine screen - Perforated plates system

Common frame for ease of maintenance

FRONT DISMANTLING: The ANDRITZ Aqua-Screen fine screen features a front-end access door. The complete rack holding the filter elements can be removed in one step through this access point. This means that downtime is reduced to a minimum, typically taking less than 30 minutes for a field service technician to change the filter elements. In addition to the time saved, this maintenance friendly design requires much fewer steps and parts to complete the operation of changing the screen filter.

ISM – INTELLIGENT, SIMPLIFIED MAINTENANCE: An innovative maintenance concept has been developed for the ANDRITZ Aqua-Screen fine screen and comes as standard on large models: ISM (Intelligent, Simplified Maintenance). The ISM system allows preventive maintenance by monitoring rail wear and chain tensioning. Sensors inform the operator before failures occur – this not only protects the equipment and plant, but also limits maintenance costs and reduces downtime.

Aqua-Screen P and T: Filter element can be dismounted from the front in less than 30 minutes

Operating principle

Aqua-Screen T uses replaceable tooth elements; Aqua-Screen P uses a stepped perforated plate with circular meshes. Both provide two-dimensional separation for higher capture and reliable lifting of screenings without fragmentation.

Cleaning systems

External automatic backwashing (spray bars) plus an adjustable high speed rotating brush keeps the filtering area clear and sustain throughput, especially with fatty or fibrous solids.

Materials and corrosion resistance

Frames and panels are available in 304L/316L stainless steel to ensure durability and long service life in municipal and industrial wastewater.

Key design parameters

Configured to channel dimensions and duty: mesh/perforation (e.g. 1–15 mm for T; 3–6 mm for P), target capture rate, and allowable headloss – matched to influent characteristics.

How to select the right screening technology? One step forward in efficient screening!

Proper screening is the first and one of the most important steps in a wastewater treatment plant (WWTP). Critical parameters must be taken into account when selecting proper screening technology as each application or project is different. The following parameters are critical when selecting the correct equipment: application, flow, load, composition of screenings (sticky, fine, etc.), size of screenings, and so on. With more than 150 years of experience in the design and manufacturing of solid/liquid separation technologies, ANDRITZ can help you find the right solution to meet your specific screening requirements.

Proper screening is the first and one of the most important steps in a wastewater treatment plant (WWTP)

ANDRITZ Aqua-Screen fine screen, the best proven screen for your needs

Explore Aqua-Screen T, the self-washing, continuous fine screen

The ANDRITZ Aqua-Screen T fine screen is engineered for high screening efficiency in wastewater treatment plants. Featuring a robust toothing system and bi-dimensional separation, it delivers superior solids capture while preventing fragmentation. Its modular stainless-steel design, combined with front dismantling and advanced cleaning systems, ensures reliable operation, easy maintenance, and long-term durability for municipal and industrial applications.

Benefits of Aqua-Screen T tooth fine screen:

- Pop-out / pop-in modular filter racks that can be replaced easily from the front of the screen with optimum accessibility for ease of maintenance

- Improved teeth design allowing increased screening and lifting capacity

- Improved capture rate

- Optimal efficiency thanks to bi-dimensional separation and unmatched lifting capacities (dimensions/quantity)

- Fewer wear parts mean reduced maintenance costs

- Versatility in combination with Aqua-Screen P fine screen (possible to convert from one model to the other to improve the capture rate)

- No submerged bearing for maintenance ease and increased lifetime

- Can be adapted to handle the most challenging applications

- Also available in off-channel, tank-mounted version

Explore Aqua-Screen P for high capture rates with perforated-plates

The ANDRITZ Aqua-Screen P fine screen features a robust perforated plate design that ensures maximum solids capture and reliable protection for downstream equipment. Its two-dimensional separation and double cleaning system—combining an adjustable rotating brush with bi-directional spray bars—deliver consistent screening efficiency even under challenging conditions. Built in stainless steel and designed for easy maintenance, Aqua-Screen P is the ideal solution for municipal and industrial wastewater applications.

Benefits of Aqua-Screen P perforated-plate fine screen:

- High capture rates of up to 85%

- Circular mesh allowing the best capture rate in fine screening

- Separation in two dimensions for higher capture rate (the same mesh vertically and horizontally)

- Double cleaning system outside the filtration area, allowing optimal efficiency

- Perforated plate has a modular design, thus fewer spare parts are needed, and the supply chain is shortened

- Versatility in combination with ANDRITZ Aqua-Screen T fine screen (possible to convert from one model to the other to improve lifting capacity)

- No submerged bearing for maintenance ease and increased lifetime

- Increased cleaning performance thanks to adjustable cleaning brush and bi-directional spray ramp

More screening solutions from ANDRITZ

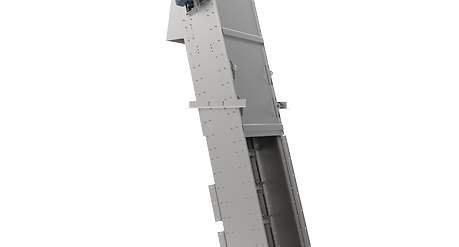

ANDRITZ Aqua-Screen B fine and coarse screens

The Aqua-Screen B multirake bar screen completes the ANDRITZ Aqua-Screen range, offering robust and efficient screening for wastewater treatment plants. Designed for both fine screening and coarse screening, it ensures reliable solid separation and continuous cleaning of the screening surface.

How Aqua-Screen B works

Aqua-Screen B operates with a series of multi-rakes driven by motorized rolling chains. This mechanism continuously cleans the screen bars and transports captured solids to the upper discharge zone, maintaining high screening efficiency and reducing manual intervention.

Installation flexibility

The system can be installed in channels up to 3 meters wide and 20 meters deep, with inclinations between 75° and 90°. It supports coarse screening with bar spacing from 15 to 80 mm and fine screening from 5 to 12 mm, making it adaptable to diverse site conditions and hydraulic loading rates.

Durable stainless-steel construction

Built entirely from stainless steel, Aqua-Screen B ensures long-term reliability in harsh wastewater environments. HDPE guides and roller chains replace gear wheels in the lower section, reducing wear and maintenance needs.

Enhanced protection and smooth operation

Specially designed bumper guards protect the screen bars, ensuring smooth operation even under demanding loads. This design minimizes downtime and safeguards equipment, contributing to overall plant efficiency and cost savings.

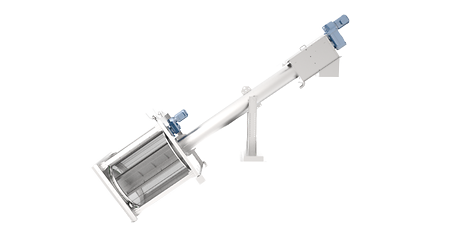

ANDRITZ Aqua-Screen S, screw screen compactor

The Aqua-Screen S allows the wastewater filtration and transport of the effluents for storage, in a practical and efficient package. This screen is a complete variant, with a compactor zone next to the discharge, which allows an important reduction in weight and volume of filtered waste (up to 50% less).

ANDRITZ Aqua-Screen MBR, rotary drum screw screen:

The Aqua-Screen MBR is used for solid-liquid separation for high flow rate and combines two operations: filtration and conveying (a third one is possible, adding a compactor). It is commonly used to be installed before MBR, using 0,8 mm to 2 mm perforated drum.

ANDRITZ Aqua-Screen M, fed drum screen:

The Aqua-Screen M is a single unit handling screening and conveying. This system integrates a washing system and gives the full warranty of a perfect and continuous efficiency of the screen during the filtration of the effluent (diameter size from 600 mm to 1800 mm for more flexibility).

Aqua-Screen B, a multirake bar screen for fine and coarse screening

Aqua-Screen S, screw screen compactor

Aqua-Screen MBR, one single unit to perform 2 or 3 functions, with or without compactor

Aqua-Screen M, two functions in one single unit (screening and conveying) for space saving

Applications

Municipal wastewater

Headworks screening, fine screening ahead of sludge treatment and biofilters; optimized solids capture to protect downstream equipment.

Industrial wastewater

Pulp & paper, textiles, food & beverage—adaptable to sticky, fibrous, and variable loads; modular concept suits diverse channels and duty cycles.

Water intake and membrane protection

River, lake, and seawater intake; MBR pre screening for fiber control. For tertiary polishing, complementary underdrain gravity filters with wedge wire elements can increase open area and filtration velocity in downstream steps.