Screening and thickening

In addition to proven screening technologies for municipal and industrial sludges, we offer a wide range of thickening technologies such as decanter centrifuges, drum thickeners, and gravity belt thickeners.

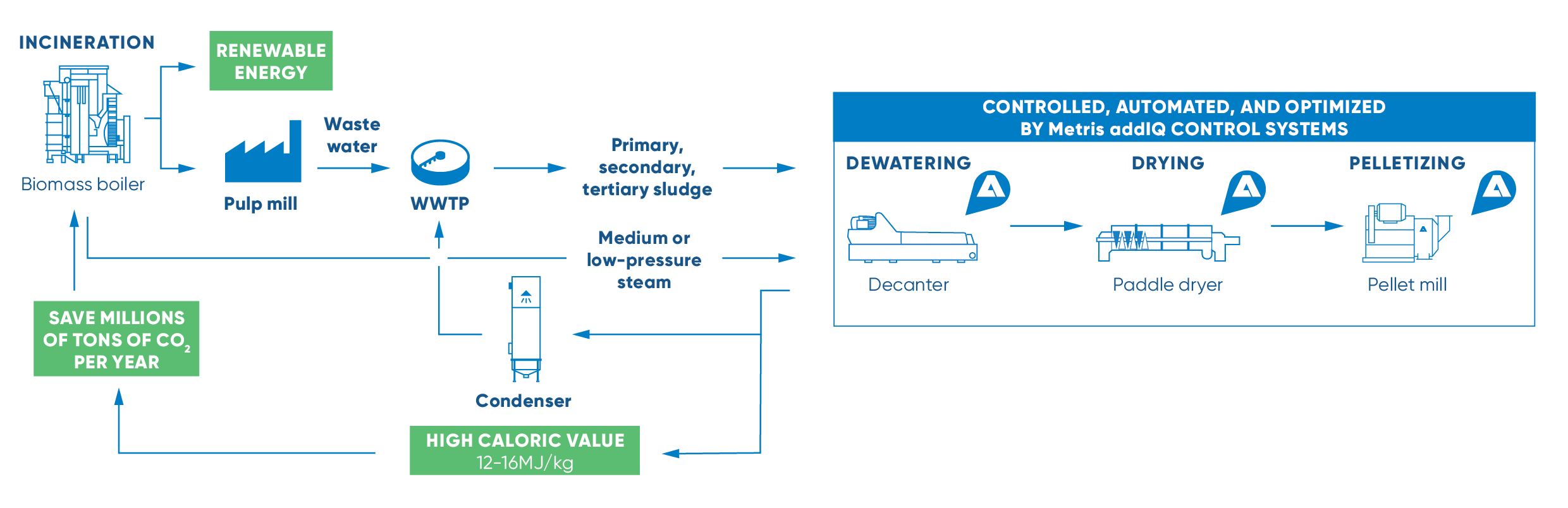

Minimize overall waste, reduce conversion costs, and reduce energy and polymer consumption. Thanks to its unique and broad portfolio for sludge thickening, dewatering, and drying, ANDRITZ can provide the right treatment to increase effluents’ calorific value, making them suitable as an alternative fuel source. With its many years’ experience in sludge analysis and its broad portfolio, you can count on ANDRITZ to select the right technology to turn your pulp mill’s sludge into fuel. Reducing polymer consumption at Leipa and a waste stream solution for transforming sludge into fuel pellets at Metsä Fibres Kemi mill are just two recent examples of how technology can help.

In addition to proven screening technologies for municipal and industrial sludges, we offer a wide range of thickening technologies such as decanter centrifuges, drum thickeners, and gravity belt thickeners.

Our portfolio of dewatering and drying solutions for nearly all types of pulp and/or paper sludge includes drum thickeners, belt filters, decanter centrifuges (for both thickening and dewatering), and multiple dryers for increasing calorific value (the paddle dryer is the most proven one). Pelletizing the dried sludge is also no problem – as is the reduction of polymer usage throughout the process thanks to Metris addIQ RheoScan automated optimized polymer dosage.

Generic principle of turning a pulp mills wastewater sludge into fuel