Susan Trast

Head of Group Communications & Marketing

On December 18, 2021, the L2A pulp drying line reached a total output of 4,672.5 air dry tons per day, which is a production world record on a single line. In terms of specific drying capacity, this corresponds to 456 tons per day and meter of working width produced on an ANDRITZ drying line for a sheet width of 10.24 meters.

Moreover, on December 18, 2021, the L2A and L2B pulp drying lines achieved a total of 8,897.4 air dry tons per day on both lines together, which is a new mill-wide capacity world record.

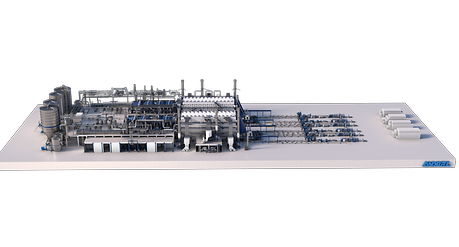

Both records were set during the first four months after start-up. This impressive performance was made possible by ANDRITZ’s leading and proven pulp drying system, whose energy-efficient pulp drying is based on the high-capacity Twin Wire Former technology, includes airborne dryers, cutter-layboy and baling lines, and is equipped with the Metris DryQ smart pulp drying solution.

Bracell’s “STAR” project at the mill in Lençóis Paulista is one of the largest and most sustainable pulp mills in the world, meeting the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

These outstanding results are based on the combination of customer and supplier partnership, good plant management and technology as well as excellent planning and implementation.

- End -

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient, and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ pulp drying plant at Bracell’s “STAR” project, Brazil, achieves new production world record