Converting renewable energy to green hydrogen.

Early engineering consultancy for P2X plants

Tailored engineering and consultancy services

At ANDRITZ, we offer specialized early engineering consultancy services for Power-to-X (P2X) plants. One of our core expertise lies in conducting planning and feasibility studies that support robust business case evaluations and successful EPC tendering.

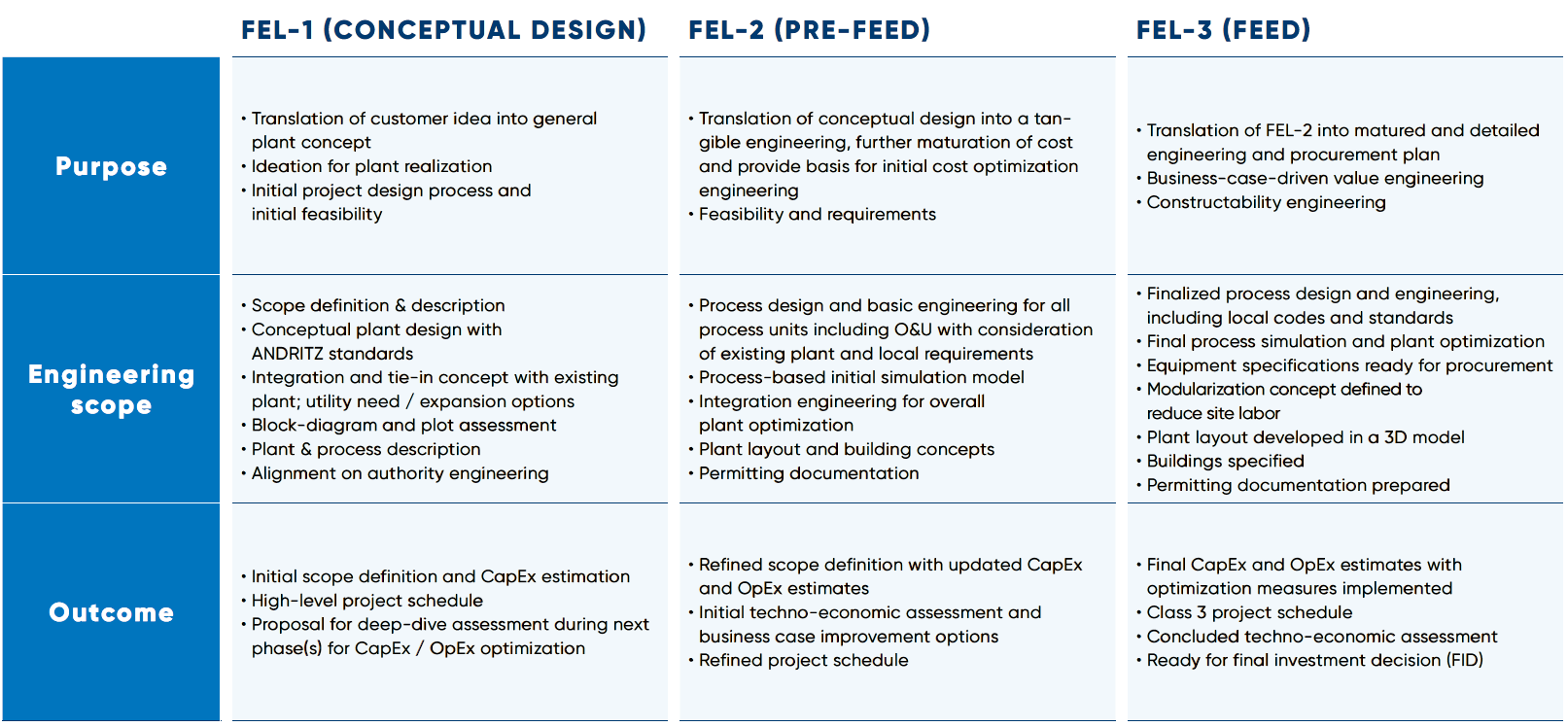

Our early engineering approach is structured into three distinct phases: FEL-1* (Conceptual Design), FEL-2 (Pre-FEED), and FEL-3 (FEED). Each stage serves a clear purpose with defined scopes and deliverables—laying the groundwork for solid business case assessments and confident Final Investment Decisions (FID). From translating your initial ideas into plant concepts and scope definitions, to optimizing designs for cost-efficiency and preparing for detailed procurement and construction, we cover the full spectrum.

*Front-end loading

Helping you make confident decisions with early-stage cost and technology insights

ANDRITZ engineering consulting approach

Customer proximity, globally from the start

Nobody can do it alone —together, we tackle today's challenges with precise and responsive communication.

With a presence in 280 locations worldwide, we can efficiently build P2X solutions wherever you want to build the plant.

Understanding of project viability requirements

To make P2X projects viable, special attention must be given to intermittent power load profiles. Our approach includes LCOP (levelized cost of product) reduction, product and by-product demand-driven operation optimization, additional revenues from by-product use, cost base improvement, and leveraging EU funding for innovative projects.

Additionally, our plant concepts reflect the best scaling and process integration for an optimum of the levelized cost of product. For this we offer a holistic process simulation, from the input of the electron to the output of the targeted product(s).

Key deliverables

In the FEL-1 and FEL-2 phases, we translate customer ideas into project scopes, prepare process diagrams, estimate costs, and align with engineering requirements.

During these phases, we help you understanding the differences and advantages of technology options. During the final FEL-3 phase, we complete process simulations, finalize engineering datasheets, prepare equipment procurement inquiries, and refine cost estimates.

At all stages we align the need for permitting requirements and deliver accordant documents, e.g. environmental impact analysis.

Your trusted partner for P2X

We offer integrated P2X solutions for the production of green hydrogen, e-methanol and e-ammonia, taking responsibility for delivering and integrating the technologies. Our plants are tailored to the customer's needs and site-specific conditions.

ANDRITZ's holistic solutions include

- Converting an idea into a detailed design and project plan

- Pre-engineering work (FEL-1 - FEL-3) to fully support the customer's FID (final investment decision)

- Executing the project plan as EPC (Engineering, Procurement, Construction)

- Providing LTSA services for the operating plant.

Why ANDRITZ

As a global company with industry-leading technologies, we provide full performance guarantees and life-cycle services for the green hydrogen plants and, as a trusted partner, make your project safe. Our widely distributed manufacturing and service centers offer responsive and reliable local support and resources.