Metris addIQ ARGOS for screw presses

Optimize polymer consumption and reduce costs by up to 25%

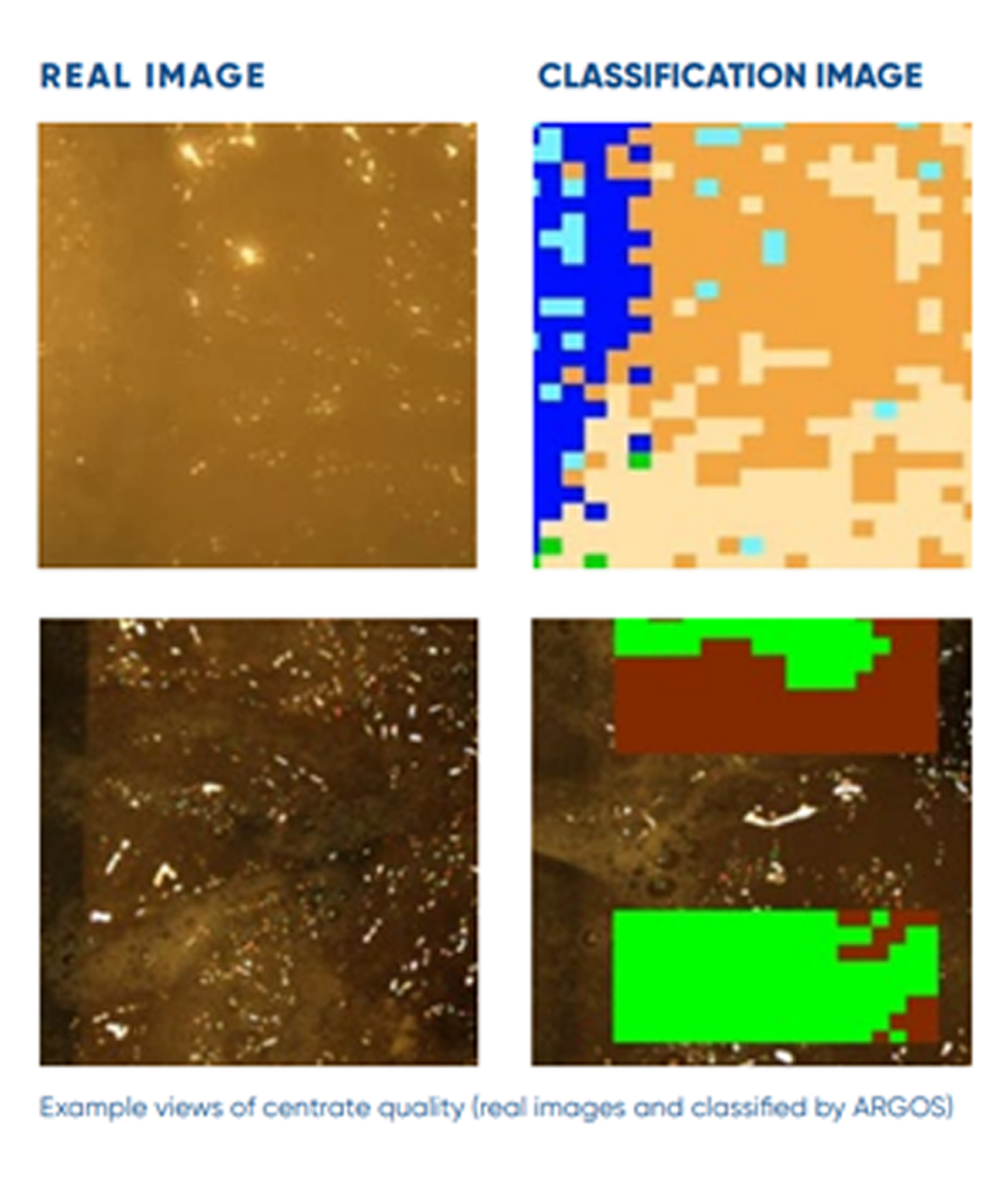

Metris addIQ ARGOS is an AI-powered optical measurement system that can detect the actual centrate condition during the dewatering process. ARGOS adjusts the optimum polymer dose to match changing conditions in the operating process - like an extra set of eyes looking over the operator's shoulder.

Adaptive cleaning sequence for increased efficiency

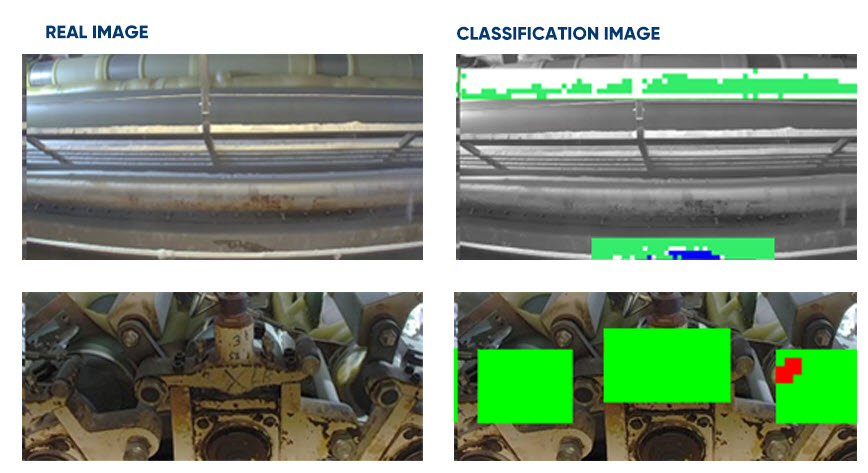

During each cleaning sequence, Metris addIQ ARGOS continuously evaluates the contamination level of the wash water. By analyzing the optical characteristics of the discharged wash water, ARGOS determines whether the machine is still carrying significant dirt or if it is already sufficiently clean.

High contamination levels tripper an increase in cleaning activity, while clean wash water leads to a shorter washing sequence. With this smart adjustment, ARGOS enhances process reliability while contributing to more sustainable and cost-efficient plant operation.

Application

ARGOS can be applied to screw presses in a wide range of sludge processing facilities. Different designs of filtrate sampling boxes are available to meet installation conditions and process requirements.

Working principle