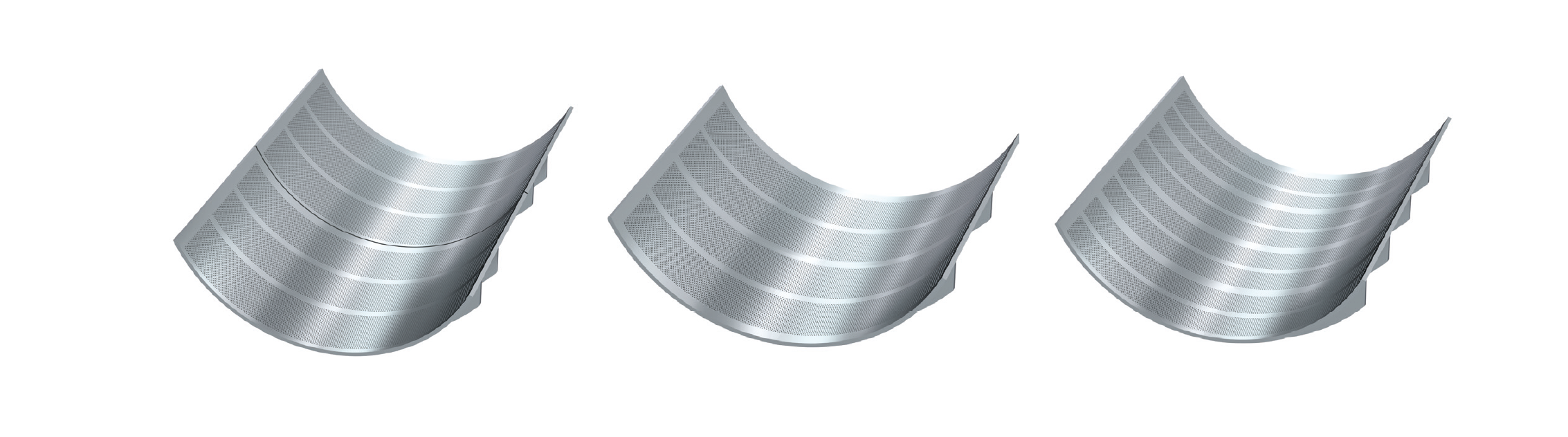

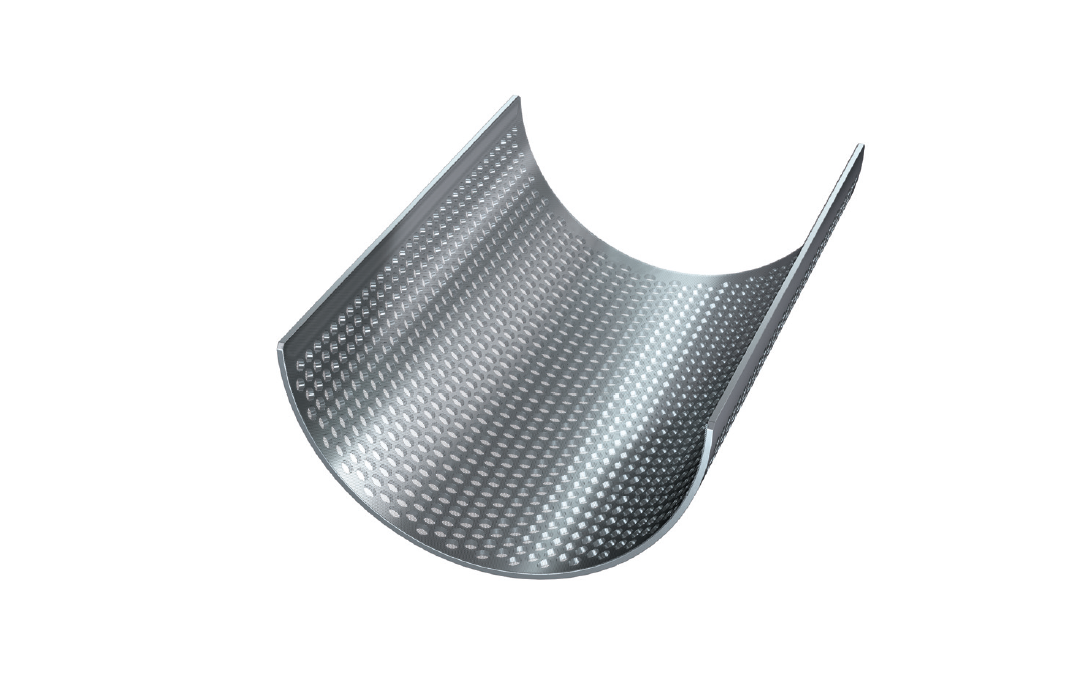

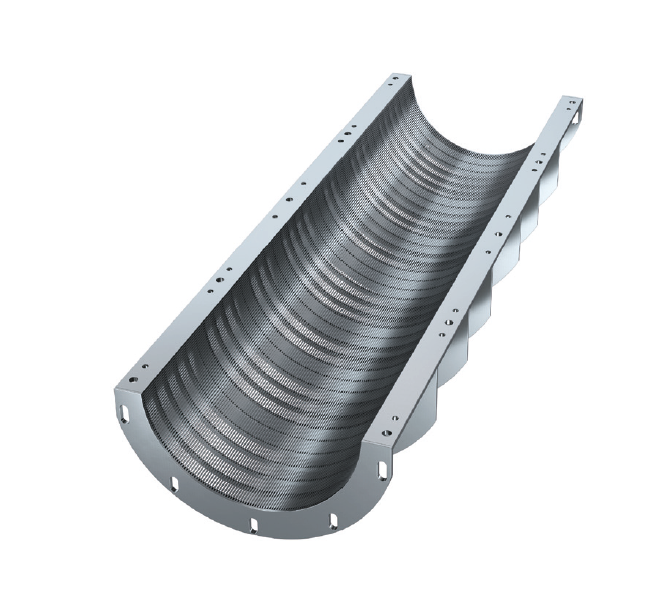

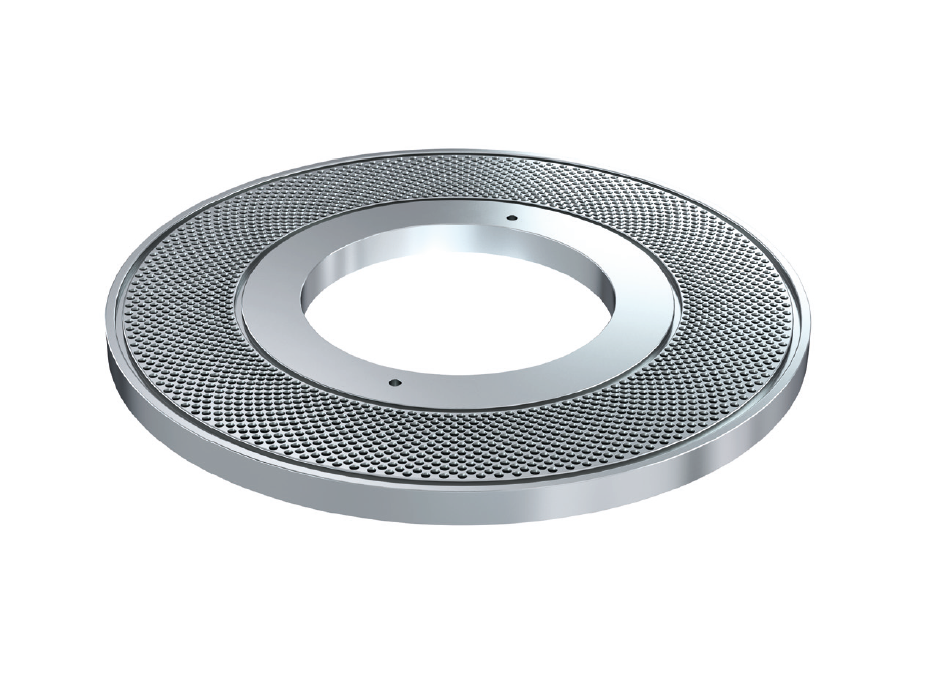

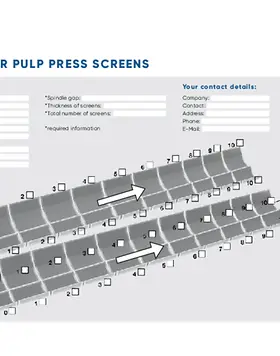

Drilled press screens

The drilled screens from ANDRITZ ensure optimal dewatering in the pulp presses and enable both a reduction in energy consumption and maintenance costs. Thanks to the maximum number of holes and an ideal hole geometry, the risk of clogging is minimised and optimum dewatering results are achieved, which reduces energy consumption for the subsequent drying of the beet pulp.

Another important aspect of dewatering is the correct distance between the screw and the screens in the press, in addition to the number of holes. The drilled screens from ANDRITZ are more resistant to abrasion and deflection, and therefore have a longer service life. This robustness is a result of the screen design and the use of particularly wear-resistant stainless steel alloys, which are perfectly matched to the requirements in the presses.

Benefits:

- High dimensional stability: no deformation in normal operation

- High wear resistance

- Low risk of blockage due to special hole geometry